Tool/software:

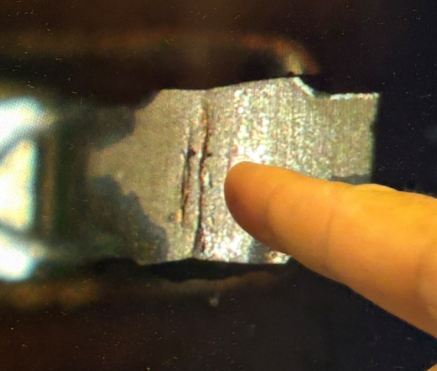

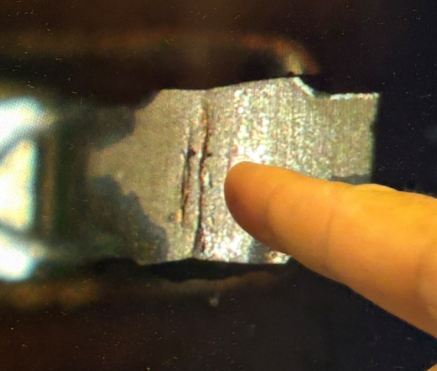

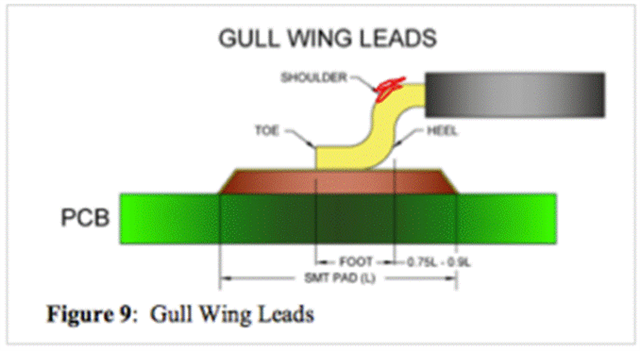

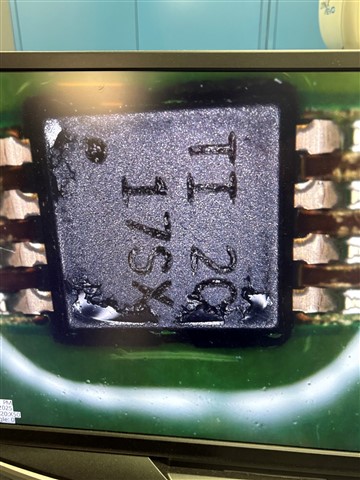

Do these lines on the shoulder of the leads look normal or is it damaged?

TPS1H000AQDGNRQ1

Pic1 is after reflow. Pic 2 is before reflow on a sample taken straight from the reel

Tool/software:

Do these lines on the shoulder of the leads look normal or is it damaged?

TPS1H000AQDGNRQ1

Pic1 is after reflow. Pic 2 is before reflow on a sample taken straight from the reel

Hey,

The leads look normal. Is there a change in device performance?

BR,

Alan

Hi Alan,

The customer has not seen a change in performance but their validation lab has flagged this with high management attention due to the exposed copper, which does not meet IPC for a class 3 component.

Hey,

Can you provide the lot information for the unit (on top of unit). In addition, how many units are affected?

BR,

Alan

We are assuming all of the units affected which is 200+.

I also pulled a virgin part from a new reel which is on the 2nd photo from the original post.

Thank you for letting me know. I will reach out to the sustaining team for further support and will update you as soon as possible.

BR,

Alan

Hey,

Sorry for the delay, the best step here would be to work with your FQE to create a customer return on these units. Then we will send it back to the assembly and test site for this case to be reviewed.

BR,

Alan