Tool/software:

Hi IT team,

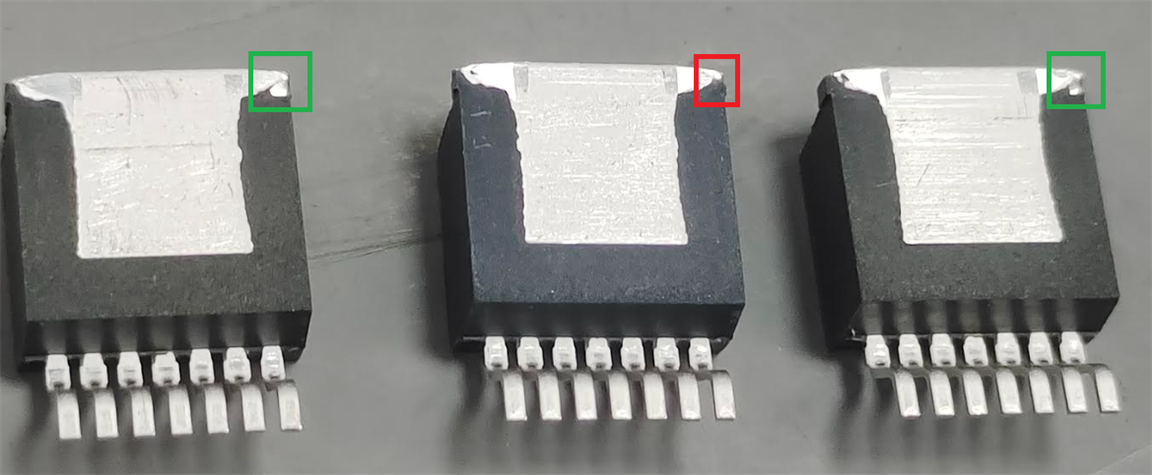

During our production today, we found that this area could not be wetted with solder, as shown in the bottom-left figure.

However, some parts could indeed be soldered in that same location, as shown in the bottom-right figure.

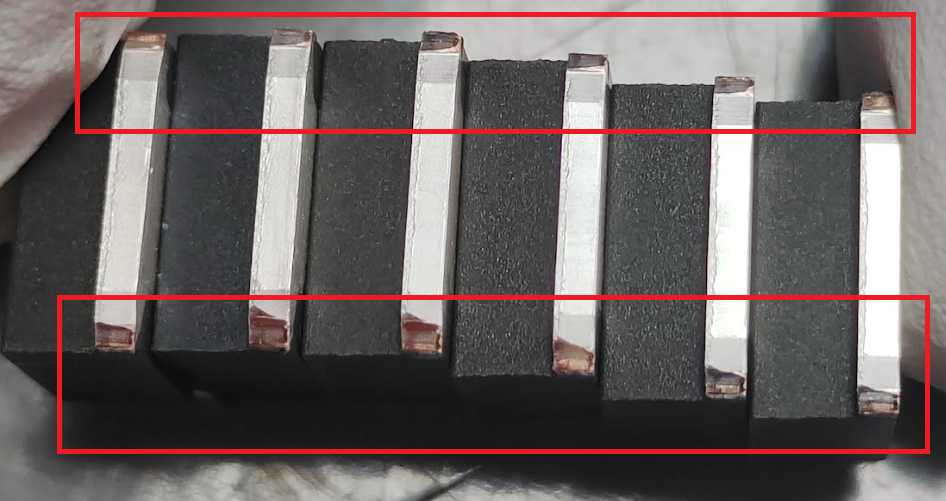

Therefore, we checked the parts in our inventory. Some parts have silver-colored pads at this end, while some others appear black and have no pads(The part in the middle of the following left figure).

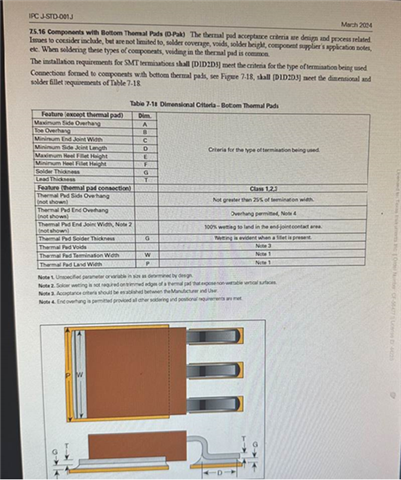

What we'd like to confirm with you is, what are the areas on this part that need to be soldered and which locations don't? It appears that some spots are unable to be wetted with solder.

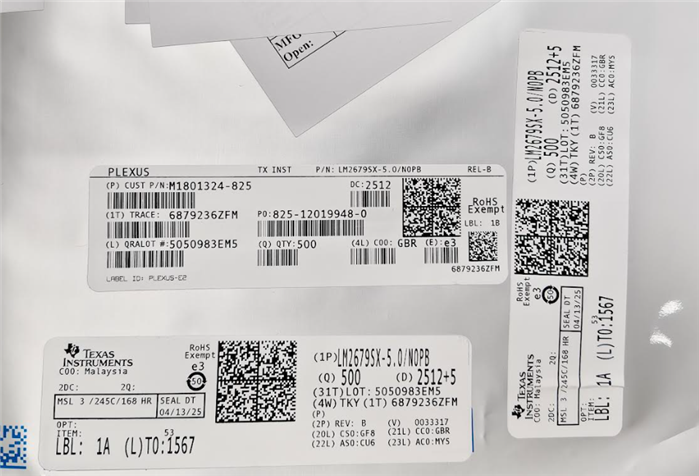

In addition, we also observed what appears to be exposed copper on the sides of this component. Is this normal? These areas do not need to be soldered, is that correct?