Tool/software:

Dear Team,

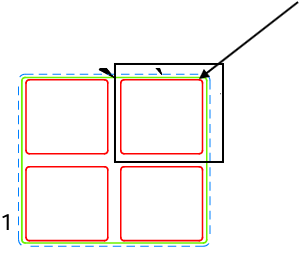

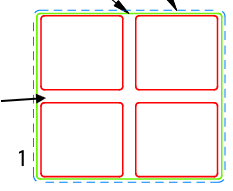

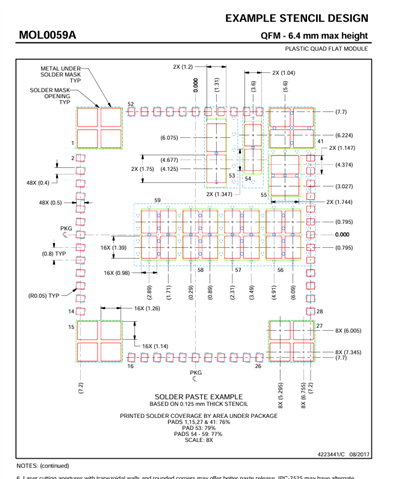

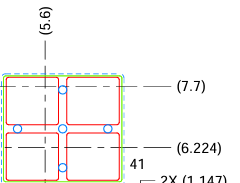

We had used the power module IC TPSM846C23MOLR in my board. We had followed the stencil design as provided in IC datasheet as mentioned

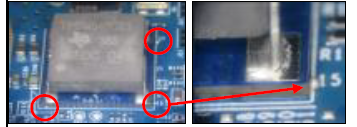

During the assembly process, after assembling the components, small solder balls are coming near the corners of the IC. In almost all of our boards, we are facing the same solder balls near the IC.

Can you please provide the suggestions on how to mitigate this issue. Please provide any updated stencil layout recommendations to avoid this issue.

Regards,

Abhishek