Other Parts Discussed in Thread: BQ25630, EV2400,

Tool/software:

Hi TI expert,

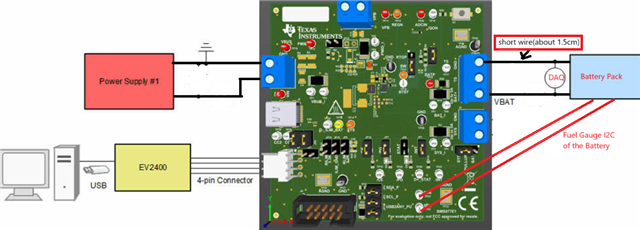

i have one problem that the battery can't be charged full (my battery CV is 4.45V) on the EVM of the BQ25630 when i set the below parameter (as below capture) and others kept as default setting, even if the charger IC entered the termination current and stopped to charge (as below charging flow data), but the battery fuel gauge info still shown the 97% voltage not 100% when i read it by EV2400(as below capture). i don't know where parameters need to be set and configured on the EVM, could you please give some suggestion on that for me? thank you very much!

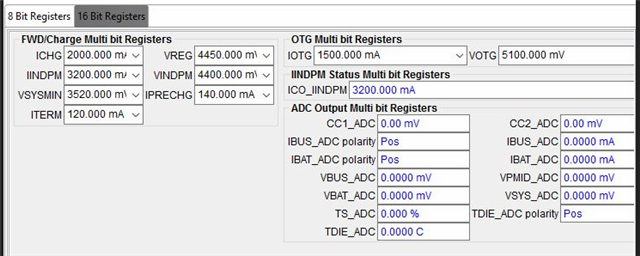

Parameter setting.

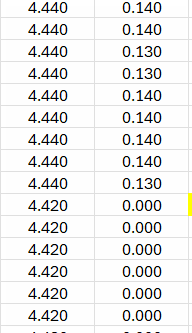

Battery charging flow.

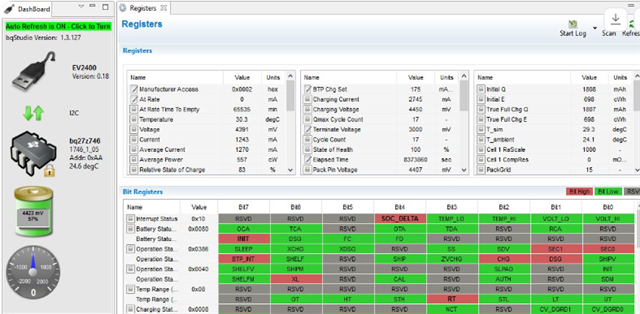

Battery fuel gauge info.