Tool/software:

Team,

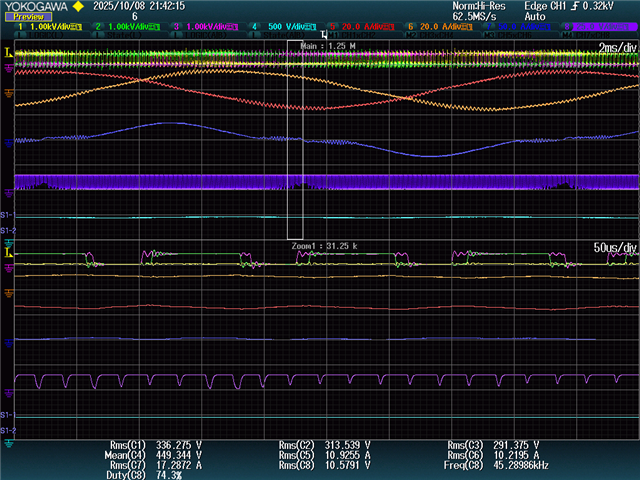

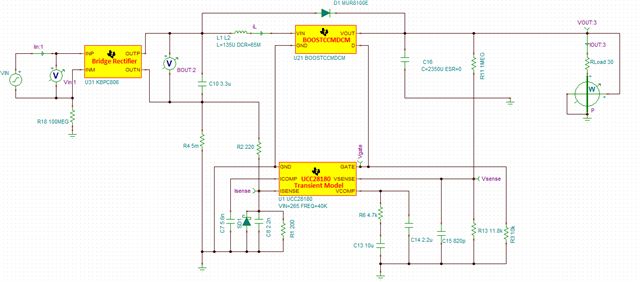

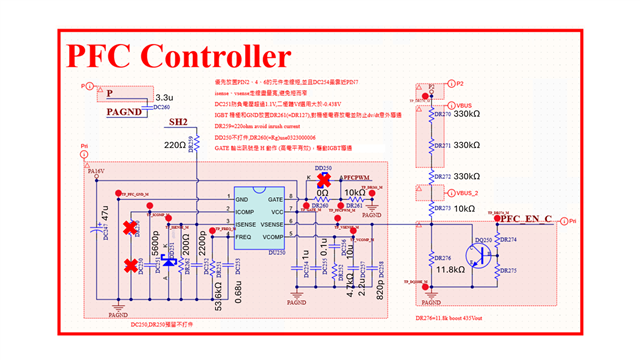

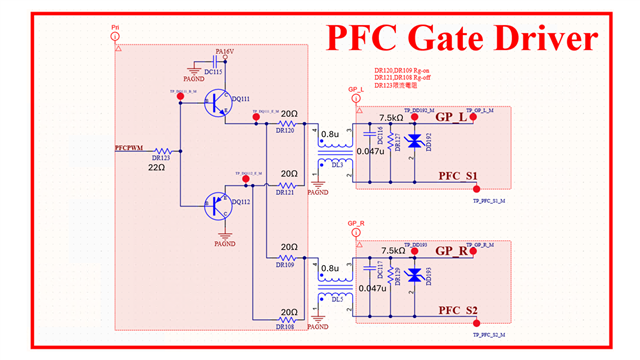

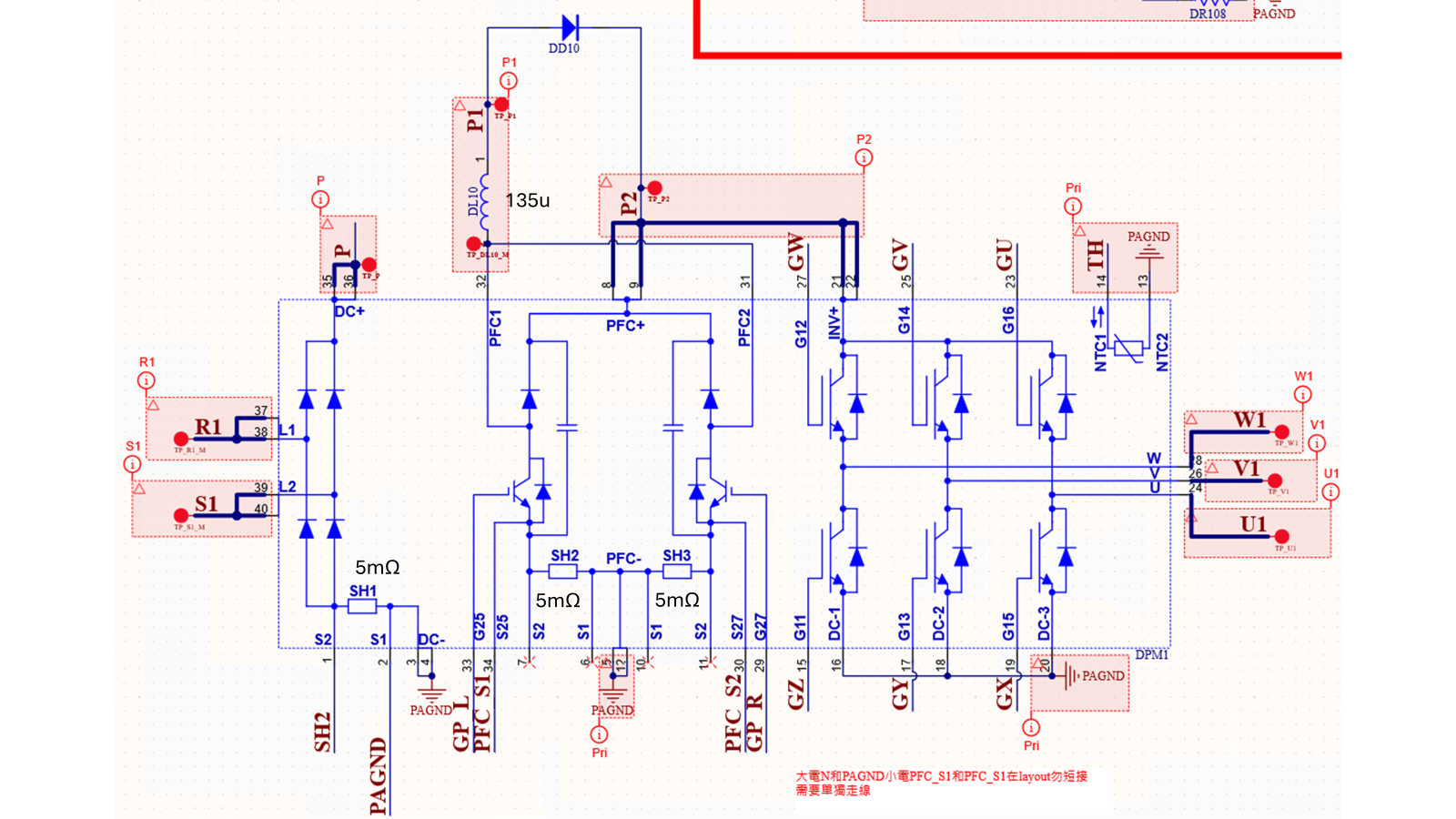

There're few questions here about the tested waveforms. The boost output DC bus works up to 435V, it's ok. But its input current as waveform with CH7(Blue color) is not likely as pure SINE wave. And the the PFC's gate driver is not switching to 0V when crossing to Zero switching period. It looks that there are difference between real on-board test and SIM result. Could you offer the comment to improve it! Thanks.

Application: AC inverter Motor Drive

CH1 : U/GND

CH2 : V/GND

CH3 : W/GND

CH4 : P/N

CH5 : U Phase Iout

CH6 : V Phase Iout

CH7 : R Phase Iin

CH8 : PFC gate driver

Spec:

Vin=220V 60Hz,Iin=17A,Vo=300V,Io=10A

On-Board Test:

SIM result:

Regards

Brian

you.

you.