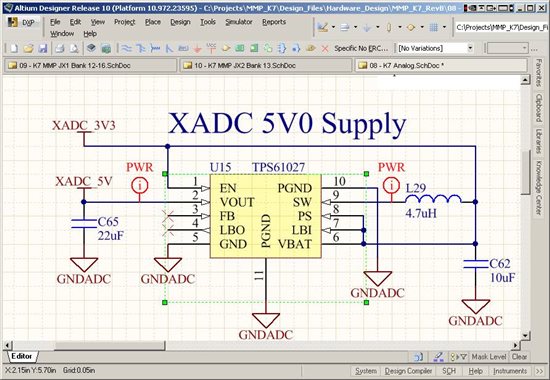

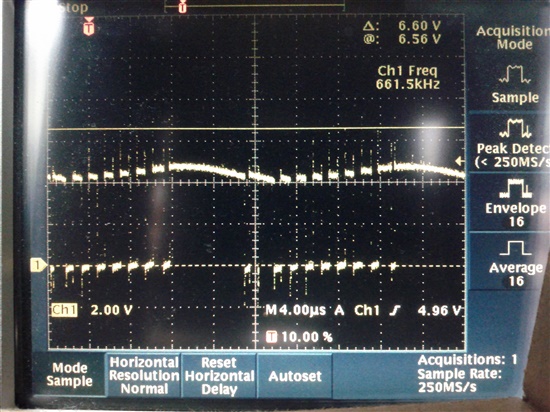

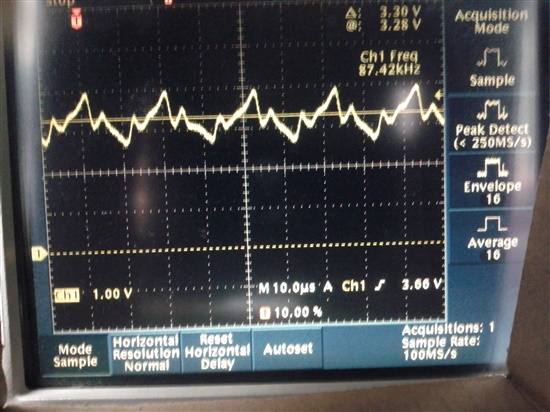

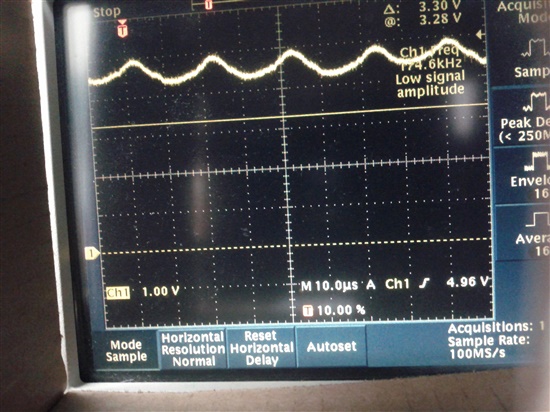

I am having a low output voltage issue with a TPS61027 we have designed into a new product, that is ready to go into production. Since this is a fixed voltage charge pump, there are no feedback resistors I can play with. I think all that is left is the inductor. The markings on the part seem to indicate the proper device. The inductor we are using is a 4.7uH NR3015T4R7M, and I am including a schematic below.

There is no load on the supply, it is attached to an external connector to supply a utility 5V for any potential external devices.

I checked the output with an ohm meter and it shows >500K Ohms, both polarities.

I note that there is mention of needing a minimum ESR, is this still true? Is there a recommended output cap that will fit, and make this work? Might I need a minimum load to make the device function properly?

The layout is very tight, with fat traces to everything.

This is very urgent for us as we are about to go into production. Your help is very Appreciated!