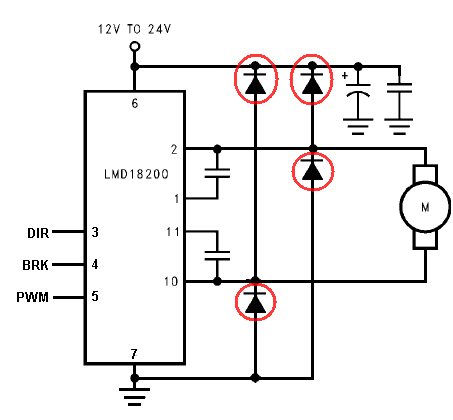

I have 5 motor drives using the LMD18200 drivers for driving 24- 850ma motors. I have now replaced 5 out of 10 of the LMD18200 on these units. I have the brake signal tied to ground and only switch the direction pin and turnon /turn off the PWM pin after a short delay. I have the boot strap capacitors in place, the 220uf cap is across the power supply but is several inches from the LMD. 2 of the failures have been definitely been where the motor leads are 70 feet from the controller to the motor.

I just did measurements this week on the output voltage from the LMD. The is a little LC oscillation when the output shuts off coming back from the motor but there are no transients greater than 24 volts. I have put in opto- couplers on the control pins and bias these at 5 volts. The 24 power supply is negative grounded.

These are all on Solar tracking motor drives - brushed motors. I tested the circuit on the bench driving motors with no problems.

I attached pictures of the on and off transitions at the terminals of the LMD18200 when driving one of the motors with 60 leads attached. 2438.Asche Solar LMD18200 Output Voltage.pdf

Thanks for any tips.

Rick Asche,PE