Hi,

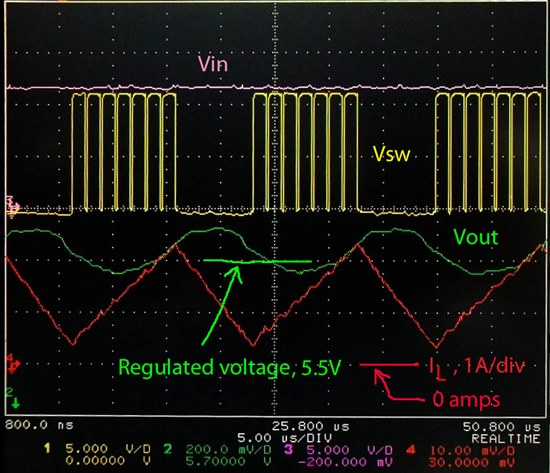

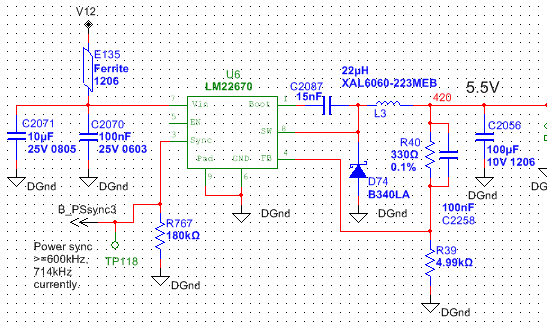

I have an LM22670-5 regulator application. When I load it with a 1-1.4 amp load it tends to kick off for 7 usec every 27usec.

The inductor current is ramping up to ~2.4A, which is well below the current limit.

The output voltage waveform does lag the current ramp and overshoots the regulated value by about 150mV. I did not have any cap on the upper FB resistor so I added 100nF, which did not change anything.

The regulator is synced to an external 714kHz clock.

Any ideas? Waveforms and circuit attached: