Hello,

we are using the LMZ10501 as a power source for two different designes (5V --> 1V, 5V --> 3.3V). At first everything went perfect and there were no issues. But until today 3 boards (2 of the first and 1 of the second design) started to get issues regarding the LMZ10501.

The power consumption of one of the design is around 120mA @ 3.3V, which should be no issue at all. The output voltage is still stable @3.3V but the overall power consumption of the board went from 110mA @ 5V to 250mA @ 5V and the LMZ10501 becomes very hot --> 60°C+ (25°C ambient). So the system is still working but the LMZ10501 should be a risk with higher ambient temeratures.

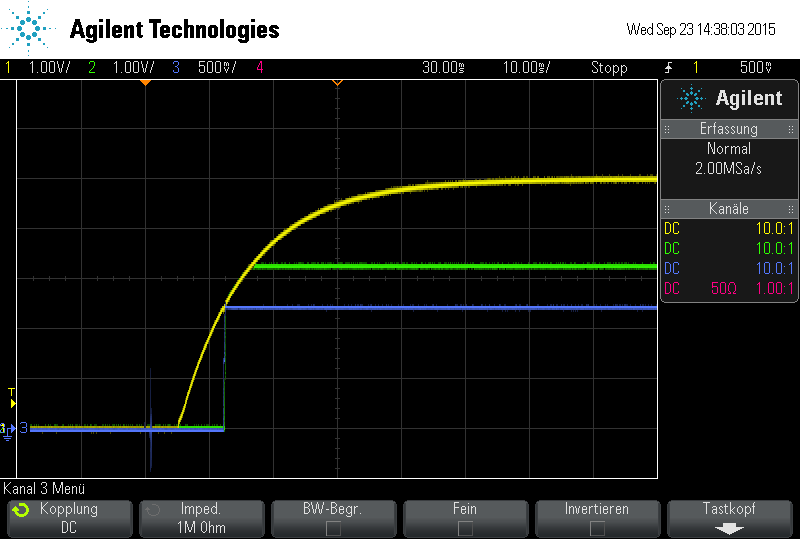

I did some research on problematic boards and found out that the enable pin (1) works differently than a working board. The pin is left floating so i can use a voltage to disable the LMZ10501. After applying 0V to the pin the output voltage is correctly disabled BUT the overall power consumption of the board is still nearly the same and the LMZ10501 is still very hot. After removing the voltage from the pin the output voltage is still disabled! That is an abnormal behaviour because it should start working again as i can see it on a working board. The only way to enable the output voltage again is by applying a voltage again. It is hard to tell which voltage because it differs everytime (somewhere between 2V-5V). After applying the voltage to the enable pin the ic is working again and i can remove the voltage.

Do you have any idea, help or advice?

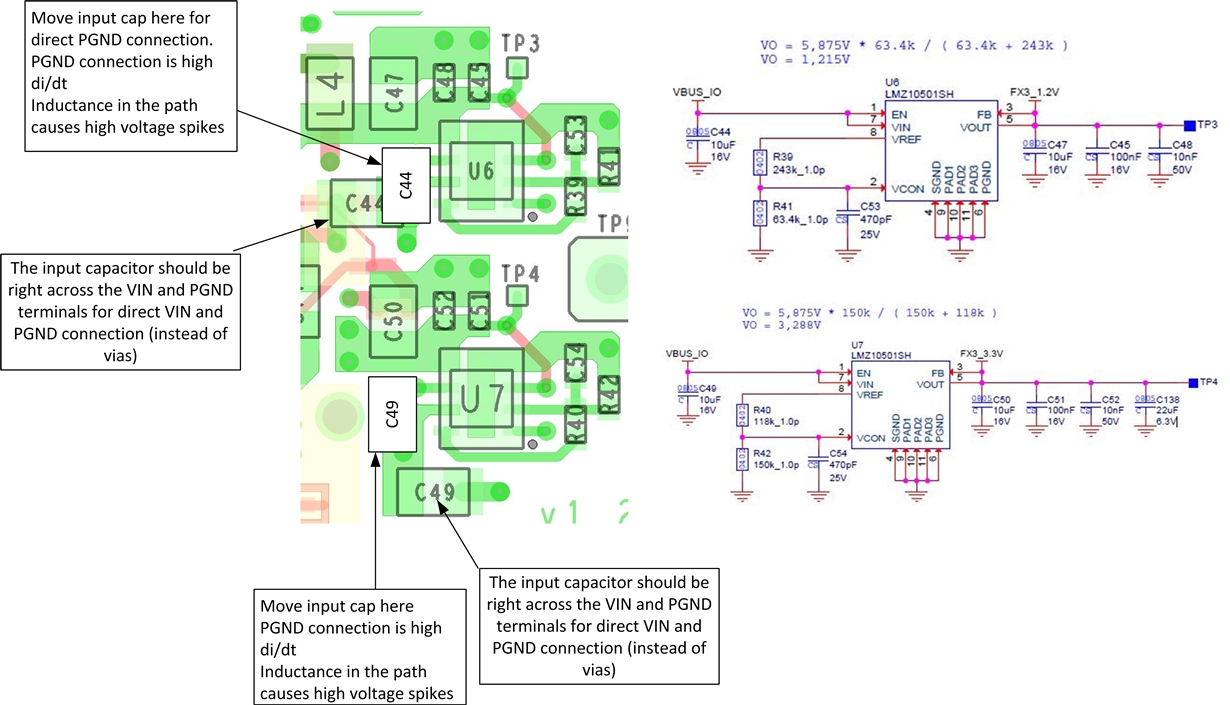

Could it be a false implementation of the device to the pcb? Maybe one of the 3 ground pas on the bottom has no connection anymore?

Best regard,

Marian