I am having a recuring issue using the LMZ10500 in two locations on a prototype PCB. Can you help determine why these parts are being damaged and assist us in fixing them?

U125 is setup to generate 2.8V and U124 is setup to generate 3.3V.

1) In the case of U125 the part fails at almost 100% immediately after intial power up. The failure exhibits the following:

- Vref pin is not reaching 2.35v.

- VREF pin is hovering at around 0.3V output wanders around 0.7 to 1.5V

- Vcon pin is 0v.

- Part is getting hot.

- The part fails again after replacement.

- We replaced this part with an LDO as a stop gap work around and this works fine.

- I have lots of failed parts that could be tested if that helps.

2) In the case of U124 the part fails after many hours of operation

- In general the part is hot and the output is 1.8V or so.

- I don't have the failed parts in hand at the moment for other measurements.

- The primary difference in the configuration of this regulator is that it has a diode on the output as per the design recommendation of the the TMS320DM368 which this is powering.

- When replaced it will operate from days to weeks with no issue.

- We are investigating an LDO replacement.

3) Will oscillation on the Enable pin during startup cause damage to the part? This has since been fixed but not on the boards that have failed and not tested long enough to not fail.

4) If there is 0.3 to 1.8V on the output after VIN is applied but before EN is high will this damage the part? This appears to be present due to leakage rom teh TMS320DM368 in our system.

Please see attached schematic: 0003.falconeye_fl-fv02-001_schematic_X12_2p8Vsnippet.pdf

And BOM: 2018.FALCONEYE_FL-FV02-001_BOM_revX13_ver2_LMZ10500parts.xlsx

Note C473 and C474 are shown incorrectly on the schematic and have been placed across R586 and R589 on the board as a modification.

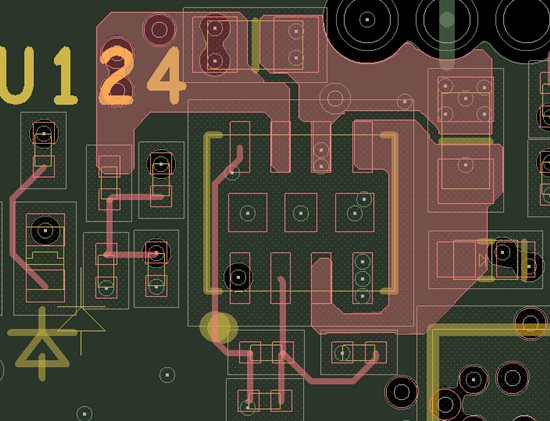

U124 Layout

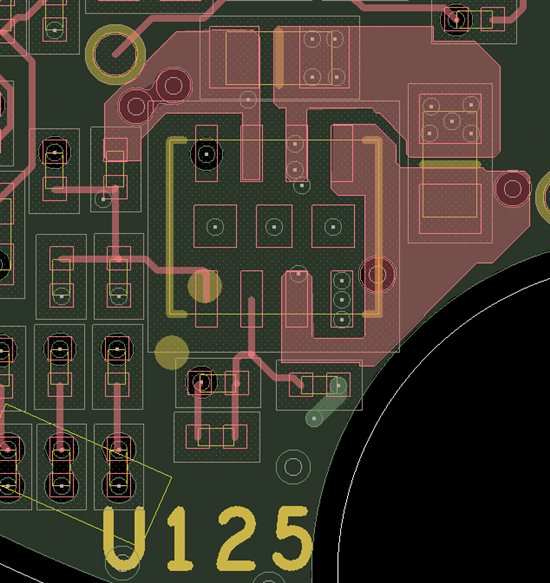

U125 Layout

Thanks for the help in advance!

Jason C