Hello folks,

I've got a couple of questions regarding the use of a TPS40210 in a somewhat brutal environment. This is an on-going R&D project for a company that I am consulting and don't want to divulge too many specifics, but I'll sketch the demands and then the good folks at TI can give me a slap upside the head, if necessary.

Application:

->Convert nominal 24V from 7 Ahr battery pack to 42 (maybe 46) V, 4 A "pulsed" output - current will only be drawn for short periods at a very low duty cycle

->The output needs to be approximately constant current (+/- 0.5 amp), not constant voltage and needs to swing from short circuit protection state (0V, 4 A) to the full output, 42 V 4A

->In a typical year, the device will only be operating for a total time of 24 hours but could be exposed to temperatures ranging from -10*F to 130*F and the equipment is portable, so shock/vibration are likely

->Cost should be kept at a minimum without sacrificing reliability. The electrical performance can be sacrificed, e.g. the voltage and current can ripple quite a bit; regulation can be within +/- 0/5 amp, etc

>>> During typical operation, I only need about 12 volts to maintain 4 amps but occasionally, I need up to 42 volts to maintain 4 amps. Unfortunately, these current bursts only last about 10 milliseconds so whatever solution I come up with has to respond fairly quickly. I do have a micro-controller at my disposal. I considered using this to enable/disable the TPS40210, but I'm not sure how quickly this will respond (e.g., the micro-controller turns on the output, detects a high resistance load and tells the TPS40210 to turn on. Then the TPS40210 has to turn on and supply a 4 amp pulse all within a about a millisecond).

Questions:

1) What is the best way to implement a constant current design? Before investigating the possibility of using the TPS40210, I had designed a very simple method of regulating current using a TIP142G, a current sense resistor, a differential amplifier and a general purpose NPN transistor. At 24 volts, I was able to produce a circuit that regulated the current to an average 3.8 amps without ever asking the transistor to dissipate more than 125 watts. I can tack this on to the output of the TPS40210 if necessary, but this leads to my second question:

2) If I tack my little "constant" current circuit onto the output of the TPS40210, is there a way to adjust the voltage output? For instance, as my differential amp turns on the general purpose NPN transistor, it shorts current from the base of the TIP142G causing it to turn off. Can I also control another resistor to pull the comp pin low? Would this drop the voltage in a predictable manner? Alternatively, can I inject my own voltage to the feedback pin to control the voltage? The idea here is to drop the output voltage to, say, 30 volts when the load resistance drops below a certain threshold. This will help prevent the TIP142G from having to dissipate too much power.

(As you've probably guessed, I'm just pretending to be an EE. By profession I am a physicist so I apologize for any abuse of terminology and for my rube-goldberg style approach!)

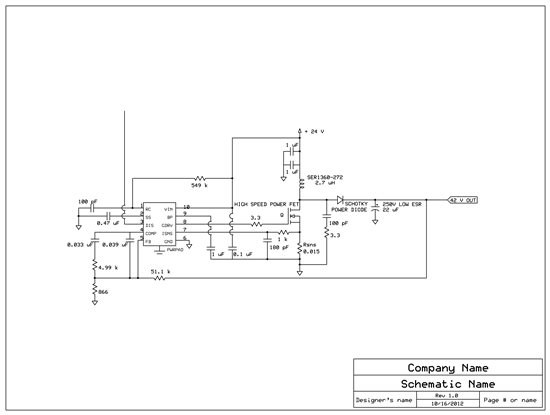

Here's the circuit (I've chosen components based largely on cost. The output ripple is fairly low allowing the use of a single, fairly cheap capacitor. The trade off is an increased input ripple current, which is handled by two cheap X7R ceramic capacitors with a high ripple current rating). I hope this looks like a reasonable design...