Hi, I designed a boost converter using UC3823N. I got a problem that no matter how adjust parts' values, the converter still works in DCM. If I increase load, the power supply of boost converter would go to current limit and decrease supply voltage(current limit of power supply is 3.2A).

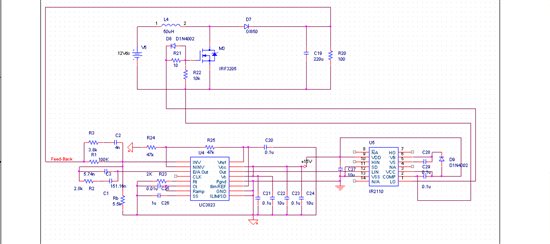

Here are parameters: input voltage 12V, output voltage 48V, PWM duty cycle, output current 2.5A(variable load). I built my circuit on a breadborad, the following schematic is my design,

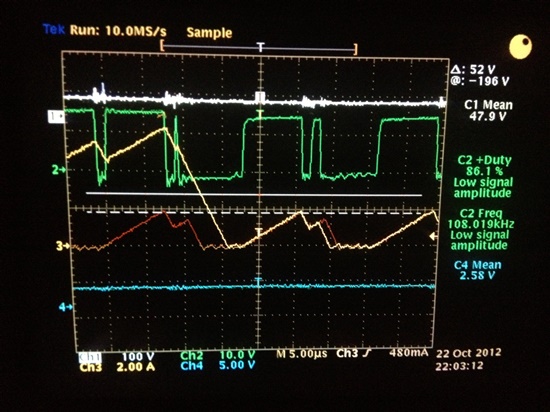

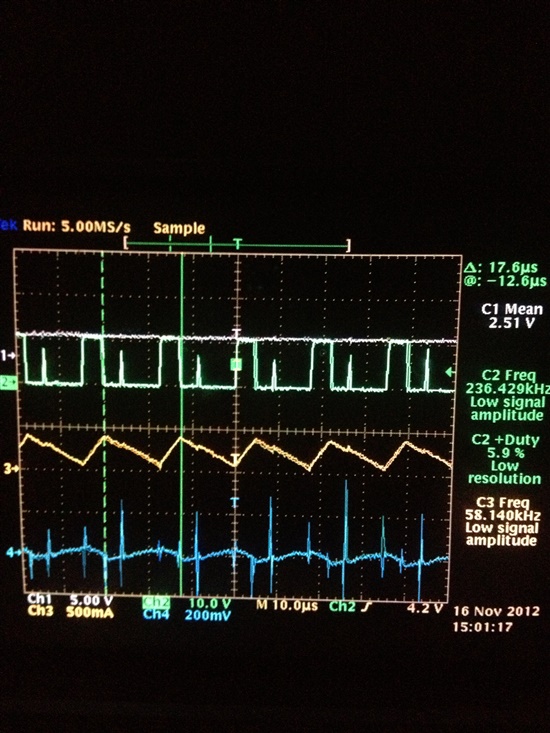

The following picture is some values of pins on UC3823N

The white line in the above picture is output voltage, the green line is output PWM of UC3823N(I know it's weird), the yellow line is input current of boost converter(it's "jumping"). The blue line is voltage on Pin 1(Inv) while the voltage on Pin 2(NI) is one half of reference voltage(pin 16), which is 2.55V.

Another interesting problem is that, if I use potentiometer to increase voltage on pin 1, the output PWM duty cycle would drease, and so does the freqency of PWM. In my design, I choose RT and CT to let UC3823N works at about 100K Hz. If the output duty cycle decreases to 30%, the frequency would also decrease to 50K Hz.

Please help me to figure out my problem.

He, Siyu