Hi all!

We are developing a simple LED circuit and are experiencing a bit of a problem with TLC5927 device. We have created a serial protocol by using GPIO. We can control LEDs as well as brightness by entering special mode. The problem arrives when we try to read error status codes.

Here is the problem: all 16 LEDs are connected and turned ON. The device ALWAYS reports '0' for all of the LEDs (e.g. error state). We have also tried to short circuit the outputs or left them opened as well. Everything that we tried yields '0'. Any clues?

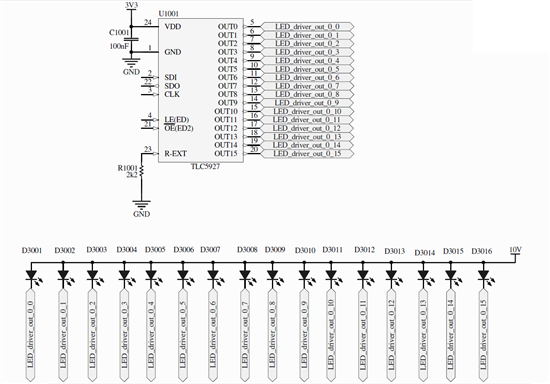

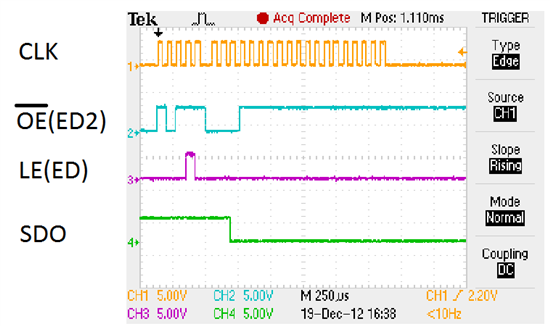

Bellow is a schematic and scope printout. We have also tried different R-EXT resistors (R1001 = 1k, 560R,...), but with no success. The datagram sent by TLC5927 can be seen in a scope printout. The GPIO pin is set to input direction, but data still remains '0' for all LEDs.

Thank you in advance for your help.

Best regards,

Matej