Hi,

Is there someone can help me find the reason why my 24vdc-150vdc converter just reach 100v.

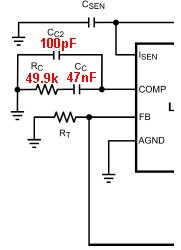

I calculate a 24V-150V 1.2A converter follow the datasheet of lm3488. The circuit configuration is same with the figure 18 of the lm3488 datasheet (plus a Rsl resister between pin1 and Rsn. the pin2 was float--- no compensation ). It works at 488Khz, the Rsl =270ohm, Rsen=9mohm, RF1=260Kohm,Rf2=2.18Kohm, l=10uH Ra=30Kohm.

When I change the Rf2, the output voltage did not change. I measure the swtch driver signal, it was just 14--25khz.

Is there someone can tell me what it is problme.

Thank you.

Dison