Hi

Question:

Average current value of BQ34z100 from I2C - 1 byte data reads

Iteupnida very well.

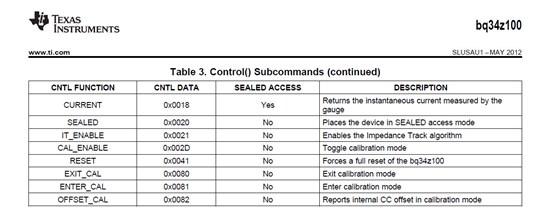

CURRENT: 0x0018 -> olryeogo to read the current value

Returns the instantaneous current measured by the gauge

Source program I2CCOMMAND (); Public get down Where Have

Questions Olympique stuffy feeling.

To a communication control microcomputer ATMEGA 128 reads the instantaneous value of current

Control () Subcommand address 0018 Read (); value 0xffff comes.

Dream, please let me know how to get favor.

Thank you very much.

Example 1:

/ / ------------------------------------------------ -----

/ / Pack_Voltage Reading

/ / ------------------------------------------------ -----

I2C_start ();

I2C_write (0xaa);

I2C_write (0x08);

I2C_start ();

I2C_write (0xab);

vt_l = I2C_read (1);

I2C_stop ();

I2C_start ();

I2C_write (0xaa);

I2C_write (0x09);

I2C_start ();

I2C_write (0xab);

vt_h = I2C_read (1);

I2C_stop ();

Tx_Pack [0] = vt_h;

Tx_Pack [1] = vt_l;

/ ------------------------------------------------ -----

/ / Pack_Current Reading

/ / ------------------------------------------------ -----

// Current 0x0018 Read 0X0000 ----- ?

I2C_start ();

I2C_write (0xaa);

I2C_write (0x00);

I2C_write (0x18); / / current

I2C_stop ();

I2C_start ();

I2C_write (0xaa);

I2C_write (0x01);

I2C_write (0x00);

I2C_stop ();

I2C_start ();

I2C_write (0xaa);

I2C_write (0x00);

I2C_write (0xab);

I2C_write (0x00);

ac_l = I2C_read (1); --> Not Read_Data ?

I2C_stop ();

I2C_start ();

I2C_write (0xaa);

I2C_write (0x01);

I2C_write (0xab);

I2C_write (0x18);

ac_h = I2C_read (1); --> Not Read_Data ?

I2C_stop ();