Hello,

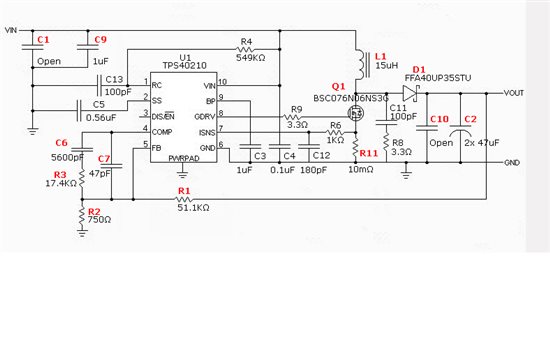

The circuit takes a 24 volt input and bumps it up to a nominal 48 volts. The designed output current using SwitcherPro Desktop is 4.2 amps. The schematic is inserted below as an image. However, when the output is connected to a test load, the switching stops. If the load is gradually ramped down, I can draw at most about 2.1 amps before it goes into overcurrent mode. Typically, it stops switching at about 1.4 amps.

The voltage on the Isens pin reaches a maximum of 40 mV, at which point it stops switching. During the overcurrent situation, the voltage on this pin falls to roughly 1 mV and stays there until retry. I attempted to short this pin to ground in order to see if I could draw more current. While shorted to ground, the controller stopped switching at less than 0.8 amps.

While there is no load, the FB pin is at 701 mV. As I apply a load, this voltage increases until reaching a maximum of about 737 mV when the controller stops switching.

These values were measured with a Keithley 197A DMM. The voltage on the Isens pin as measured by a scope is very noisy. I increased the capacitance from 180 pF to 1000 pF, which reduced some of the noise on the signal but did not improve the situation.

Any help would be greatly appreciated.