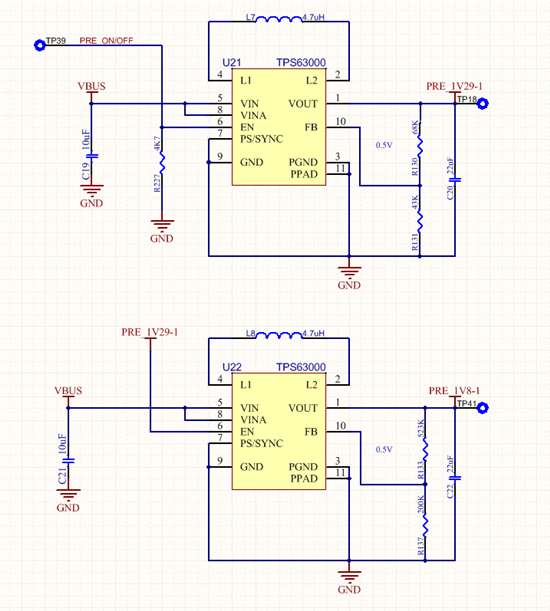

We are using two TPS63000 devices to generate two of the supply rails for a C6000 DSP (TMS320C6746). Due to the power-up sequence requirements of the DSP, the voltage rails are cascaded with the 1.29V supply driving the enable line of the 1.8V supply. Even though the minimum "ON" threshold for the enable pin on the TPS63000 is stated as 1.2V, we have found that our 1.29V enable signal is still not high enough to consistently switch on the TPS63000 (some times it does, some times it doesn't).

This problem seems to be limited to our latest production batch only and I was wondering whether there had been any similar complaints received for a specific revision of the silicon, or perhaps a specific production batch of TPS63000 devices?

For reference, our schematic is shown below: