Dear TI team,

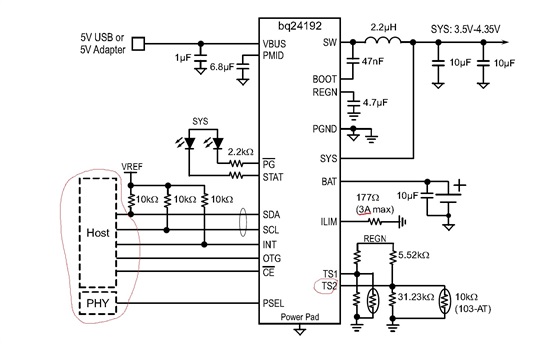

As for your suggestion we are choosing bq24192 charger IC for our 3.7V,20Ah Li Polymer battery,it will charging at 4.2V,4A. But we have some doubt in application circuit. Please advice for the following queries.

1. We don't use host for register configuration,but we need to charge at 4.2V,4A. Is this possible to achieve? If yes, how to achieve? Advice.

2.Battery charging voltage is 4.2V or its adjustable. If adj how to fix it for 4.2V

3.In circuit there are 2 thermisters. What is the purpose of 2? Can we use only one thermister? How?

4.We need 4A charging current.What i have to do for getting 4A?

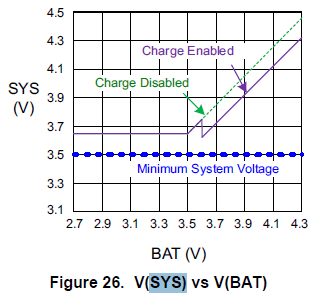

5.SYS voltage = BATTERY voltage or its proportional to each other? Please advice.

6.We have 5V,4A supply,But in circuit mentioned max 3A.Can we give 4A or i need to limits for 3A?

Our device working well at 3.4 to 4.5V,1.2A . If any changes (components/values/any) required in this circuit please advice we need to design PCB and all.

We will appreciate your earliest response.

Best Regards,

Naveen K