Hello,

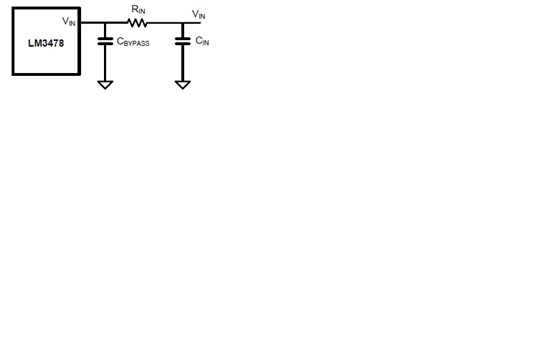

We are having an issue in production with the LM3478 that we believe is the part reaching 100% duty cycle, and once it hits 100% it just shorts the input and it can't recover. That event can occurs pretty often especially if there is a low current limit at the input power supply.

We are looking for a drop in replacement. I see that the LM3488 is pin for pin, but I can't tell what is different between the LM3478 and 88? I don't know if it would solve our problem.

Thanks for your help