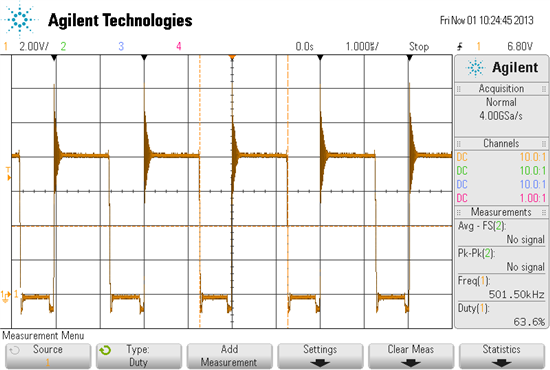

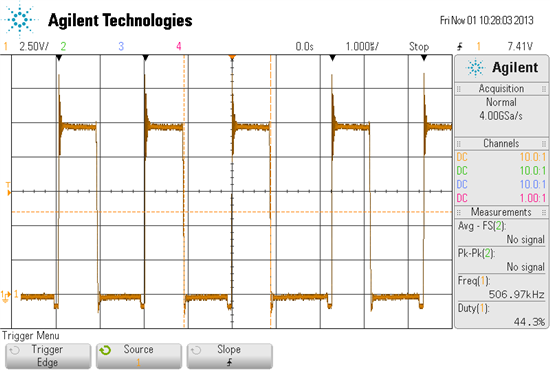

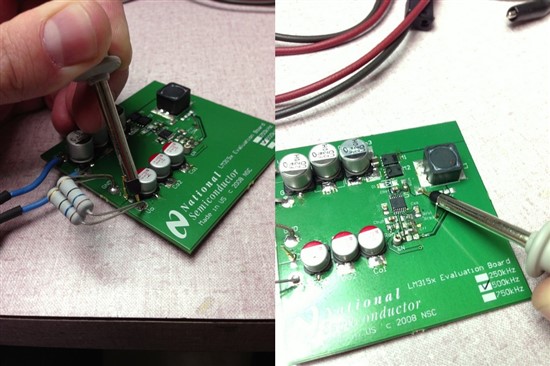

I am having issues with excessive output ripple using the LM3150 eval board. The design goal is a 5V 1A output with 2.5A transient capability and 8V-32V input. I have replaced several components on the board. The input caps are 3x220uF 50V electolytics and a 10uF 50V X5R ceramic. The output caps are 3x150uF 10V electrolytic polymers. Both FET's are TI CSD18504. Ron is 112K, RFB1 is 4.99K, RFB2 is 73.2K, and the inductor was replaced with a 47uH 1280 3A part.

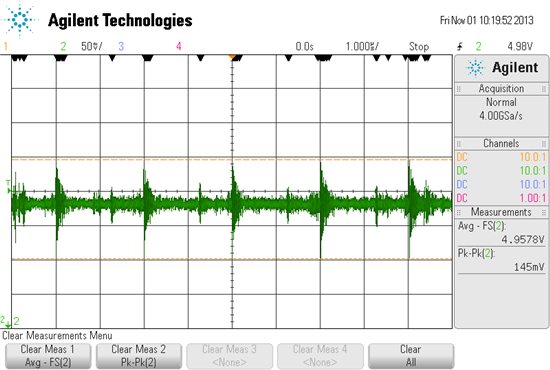

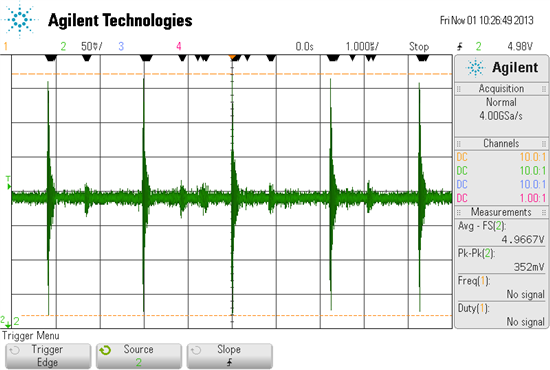

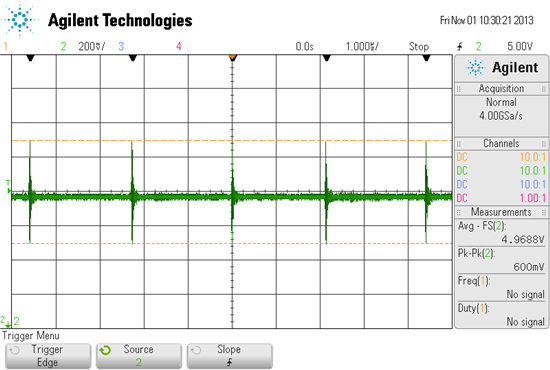

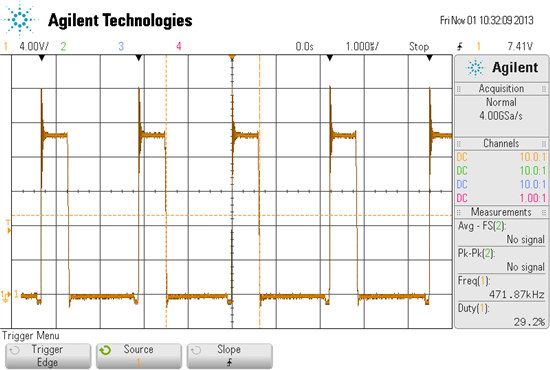

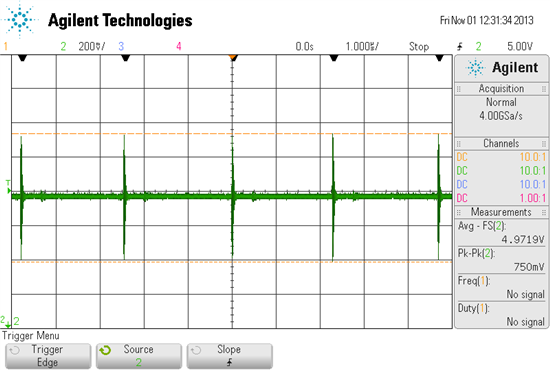

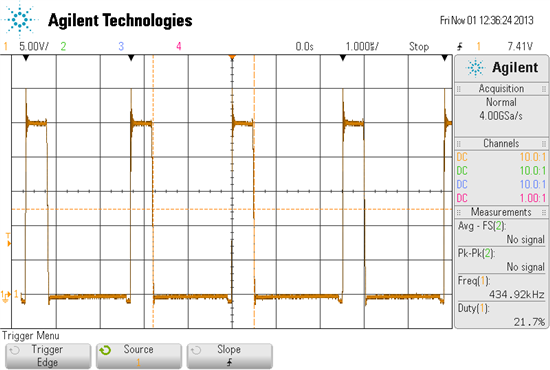

I have begun some basic load testing around 0.6A with load resistors. The output ripple is a manageable 120mV below a 10V input voltage. The ripple starts increasing above 10V, topping out at 750mV with a 18V input. The ripple stays around 750mV as input voltage increases.

Any idea what's going on here?

EDIT: I incorrectly listed a few of my component values. RFB2 is 36.5K abd RON is 102K.