Hi,

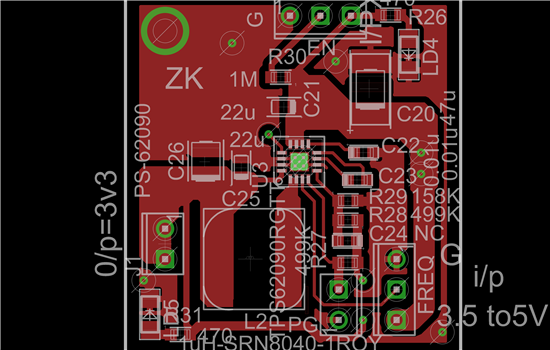

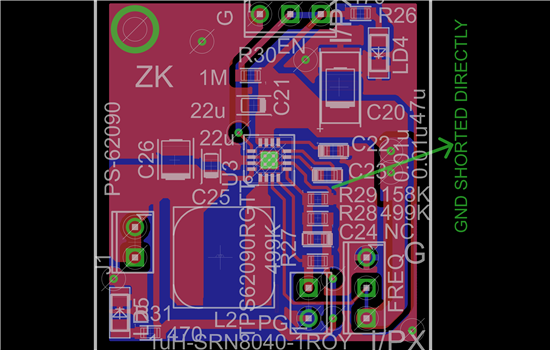

We are using TPS62090 regulator(chosen by using web-bench) for our device(which consumes approximately 1A,input voltage for regulator is 5V dc). Initially all the things are working fine, but after few days (sometimes it will be in hours) the regulator will gets spoiled/ will give troble. Means the Vout(SW) and GND pin gets shorted and we getting 0V in SW pin. We replaced regulator so many times but we getting same issue.

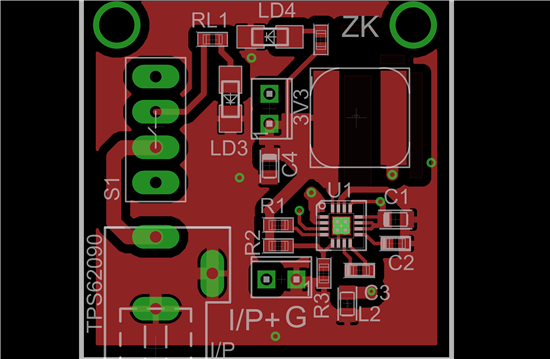

Please check the layout diagram and provide your best advice to solve this problem.

Regards,

Naveen K