Hi-

I'm working with a prototype of mine that is using the TPS61202 to generate a 5V rail from a LiIon battery in order to charge a USB device at 500mA. I have noticed occasional failures on multiple boards that I cannot yet explain. The failure mode is that when I plug the load into the board, the 5V switcher draws ~1-2 amps until the chip smokes.

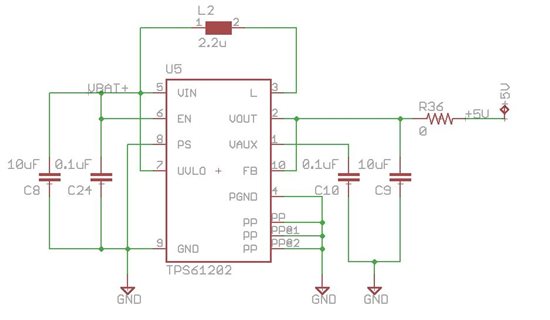

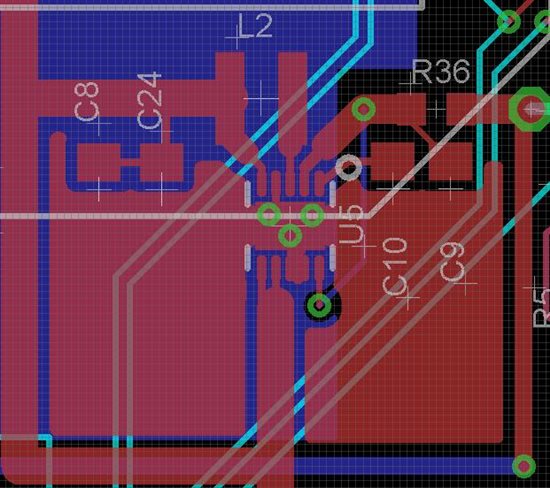

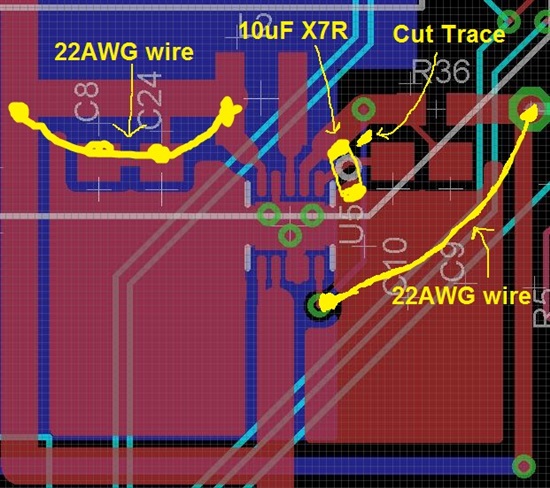

The circuit and layout are very similar to one listed in the datasheet, but I've attached them here to show what I'm doing. In probing the inrush current, I notice that the target can take as much as 2A for 50uSec when operating correctly. I am also attaching a scope shot that shows ch1 having 200mV across a 0.1 ohm series resistor to measure current, and ch3 showing the 2V dip that the supply does when the initial current spike occurs. The response of the switcher looks well damped in this instance. I have not been able to scope the system while a failure occurs due to the inconsistent failure rate.

Has anyone seen similar behavior? Any ideas as to what might be the root cause? Thank you!