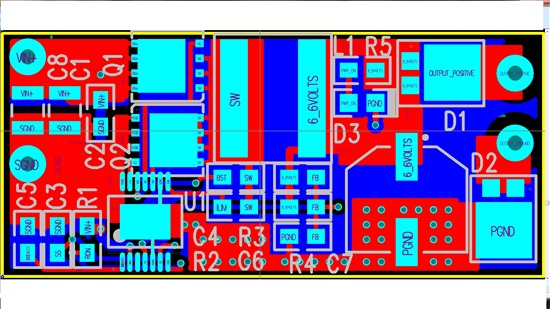

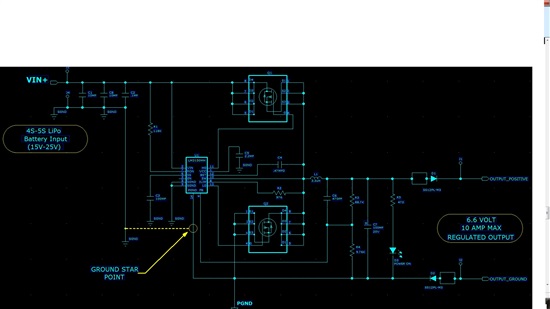

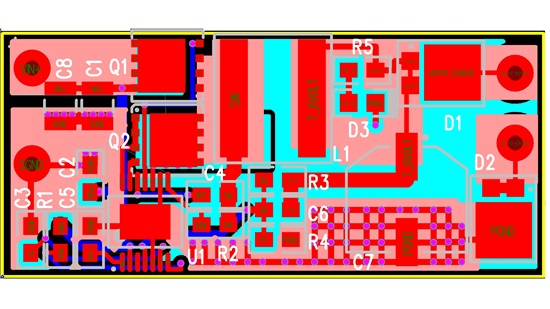

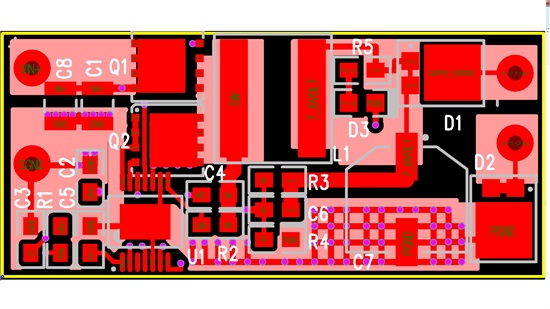

I just finished the layout of a buck regulator board and would like to see if I can avoid some problems by having a second set of eyes look over the design.

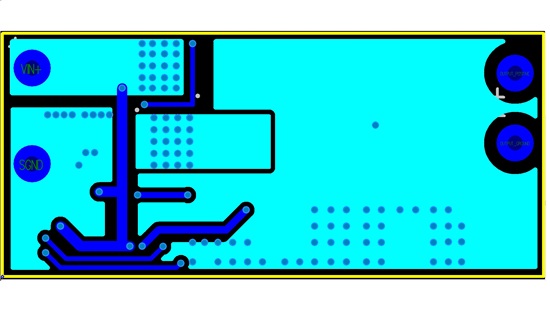

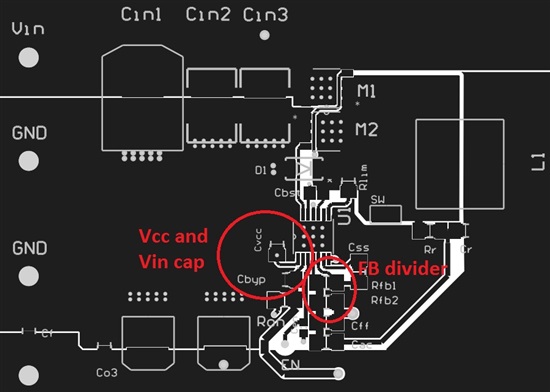

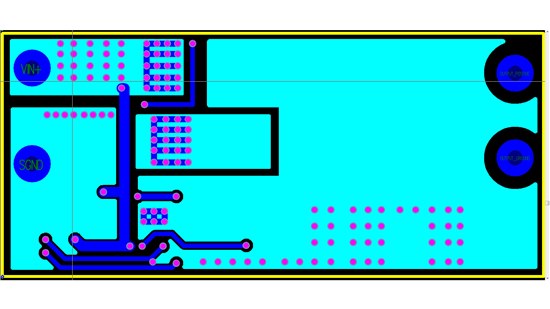

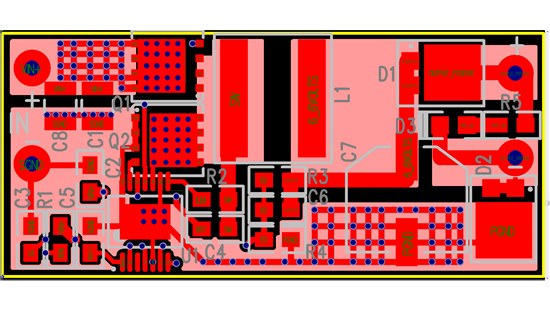

I have attached both the schematic and the board layout and would welcome any and all suggestion that would result in a stable and quiet design. You will note that the board is not a multi layer but simply a two sided design.

Thank you very much for your help!

Steve