Hi,

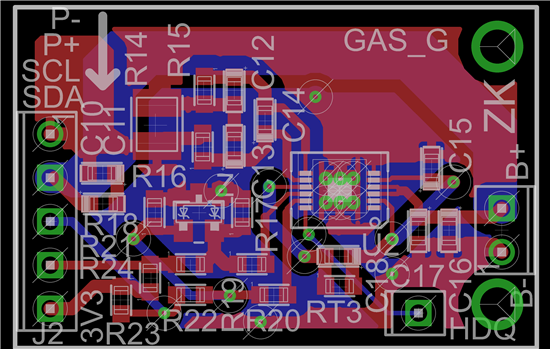

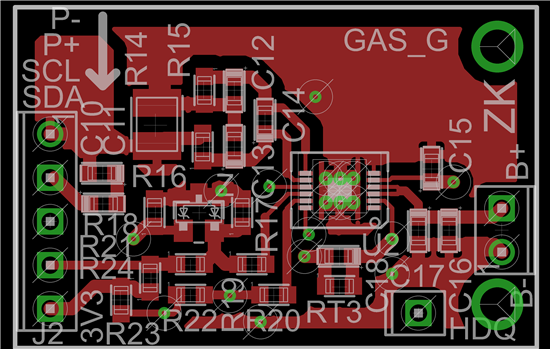

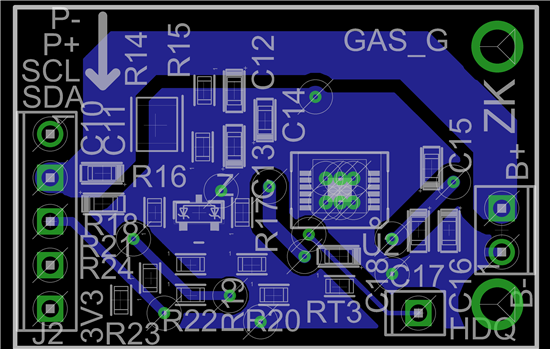

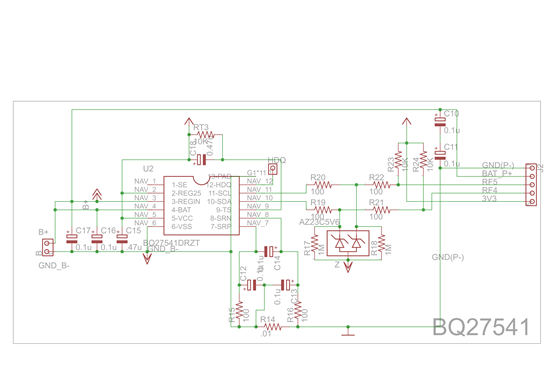

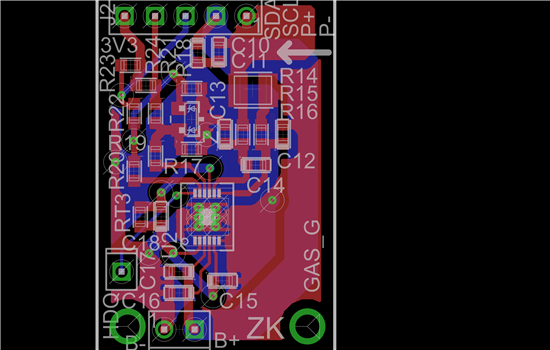

We are using BQ27541 gas gauge IC for our battery application. I have referred TI evaluation layout design for our new design which is shown below. So please check and verify the design and Let me know any changes required for our new design. So that we can give it for PCB manufacturer.

Regards,

Naveen K