Hi,

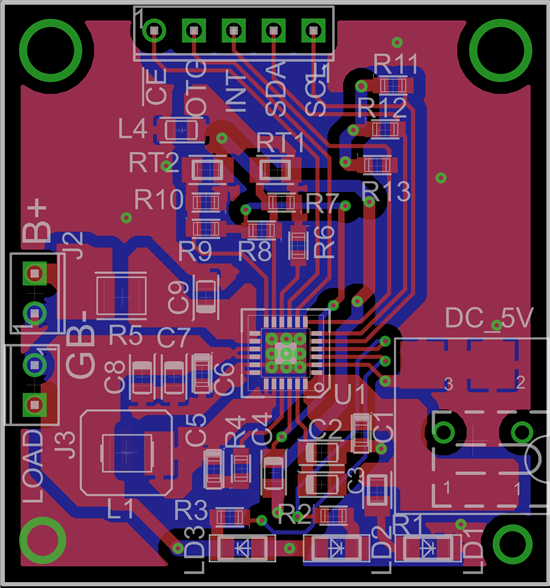

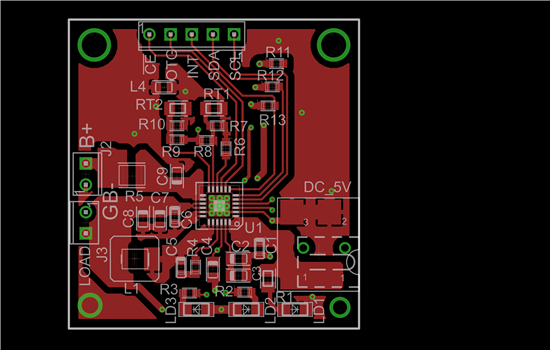

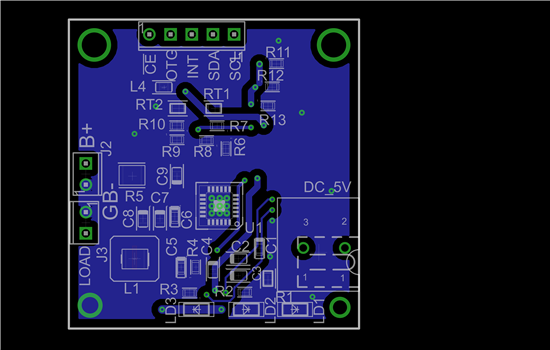

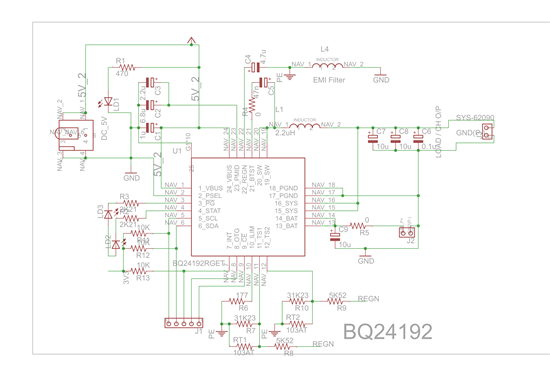

We are using BQ24192 charger IC for our 3.7V,20Ah Li-Poly battery application. I have referred TI evaluation layout design for our new design which is shown below. So please check and verify the design and Let me know any changes required for our new design. So that we can give it for PCB manufacturer.

Also Advice we need 4A/maximum charging current,So is there any changes required in this design?and How to achieve 4A/maximum current?

Regards,

Naveen K