Hello,

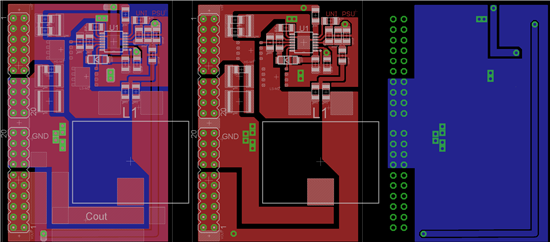

I would like to ask, if Webench calculations of efficiency are really reachable. Because wee have created universal PCB for 3.3V@5A, 5V@5A and 12V@8A(design attached). Currently we are testing a version of 5V and Webench calculated efficiency up to 97%(file attached), but we can´t get over 89% of efficiency.

In last design we used 105um PCB, which increases average efficiency from 87% to 89%.

Latest measurements:

Vin 28V, Vout 5.00V, Iin 0.01A, Iout 0.00A

Vin 28V, Vout 4.99V, Iin 0.09A, Iout 0.44A - 87.1%

Vin 28V, Vout 5.01V, Iin 0.85A, Iout 4.15A - 87.4%

I don't think, that there is a mistake in selected parts. So maybe we still have some troubles with PCB layout or the values given by Webench are unreal...

Could you please help us to find out what's wrong? Thank you

*Dbst, Cr12 and Rr12 not used in 5V

Webench data: 2045.lm3150-5v.pdf