Hi,

I'm trying to find the best driver for my application but I haven't be able to decide. I think I can get some help choosing here.

I need to control the brightness of 4 groups of dual LEDs independently. The driver have to be as small as possible. The LEDs can use up to 70mA. The change in brightness should be fast, 600uS max between complete brightness set and turn off. I only need 8 leves of brightness so if there is a part that doesn't use PWM to control the power would be even better.

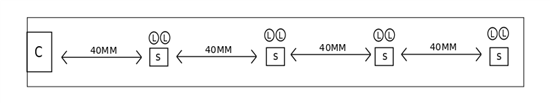

The setup is as the following diagram:

S are light sensors, L Leds and C a connector where all control signals and power come from.

So I was trying to look for a driver like a ws2811 for each group so the current loop could be reduced. The closest thing I could find was the TLC59731 but it only can deliver up to 50mA of current. I couldn't find any other driver that had an small package and low component count.

Then I thought of using a TLC5916 (8 channel) and then it would control a TL4242 for each LED. But then this wouldn't be fast enough and less cheap.

So now I think I will use the TLC5916 close to the connector and from there control the 8 LEDs. I will separate the power supplies of LEDs and Sensors but I still fear I will have high emissions.

So what would you choose in my case? Do you know any better solution?

Also I would like to know how does the TLC5916 implements the Current Gain Control since is not clear in the datasheet. It seems to be just a linear implementation and I would like to know if this is correct. I mean, the method of controlling the current in the LED is not PWM. This is important for me because if I set the current to 30mA for example I won't have to wait several cycles of a PWM to get the correct reading from the light sensor.

Any help will be greatly appreciated!