Ok, I'm starting out with the Bq34z100EVM module to try to track state of charge of a single 3.2v - 10 Amp Hour LiFePo4 battery to keep things simple.

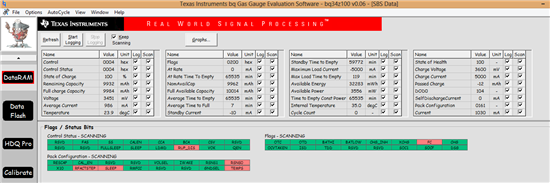

I am using the EV2300 to interface the EVM with my laptop. I'm using the BQ Evaluation software for this board and the software detects the Bz34z100 EVM chip just fine.

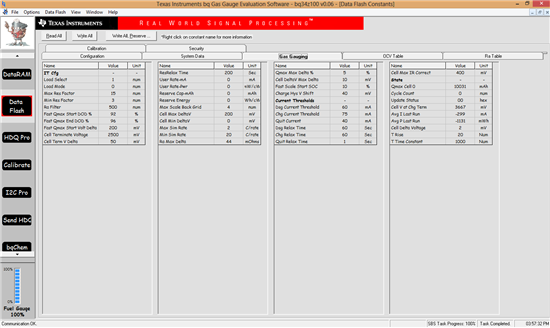

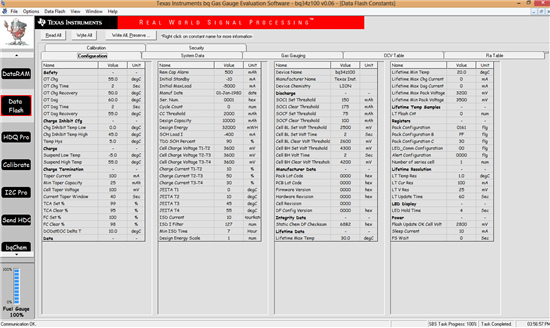

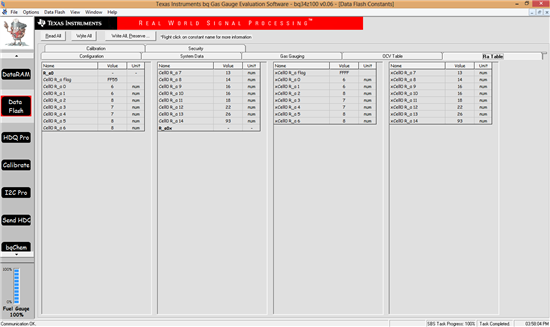

I have been able to program the Bz34z100 chip with my battery data like charge voltage, capacity, taper current, I first loaded the correct Bq battery chemistry profile for the type of battery chemistry I'm using. I have calibrated the chip also.

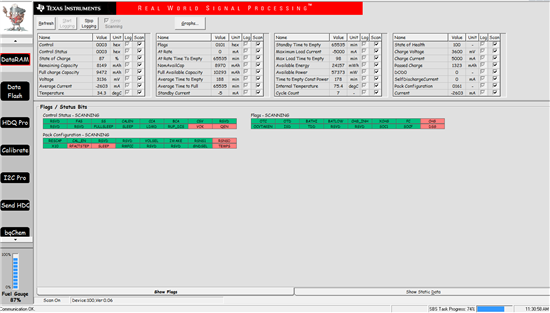

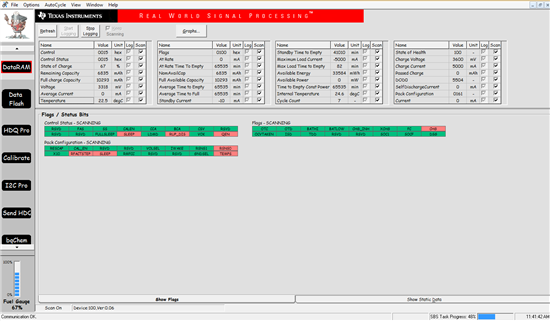

I can charge the battery from a power supply just fine and the software shows the current going into the battery just fine even up to 5 amps of input current. The State of Charge updates to 100% fully after the full charge parameters are met.

The Reg25 pin is showing 2.5 volts.

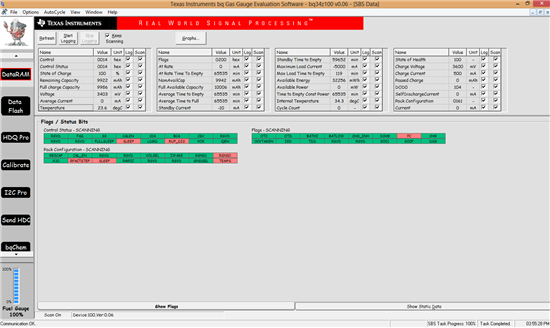

I am having a issue as soon as I try to discharge the battery through the EVM module.Tthe Bz34z100 chip instantly starts getting really hot and eventually stops communicating with the BQ software over the course of 1-2 mins after I plug in a discharge load. This will happen with a 40ma load or a 2 amp load, the same thing happens either way. I have not damaged the chip in any way and it seems I have everything setup right based on everything I have read.

When it gets hot it will pull about 500 mA @ 3.6v continuously. What could cause this? I'm assuming maybe it has to be when something notices a discharge current flow and that causes the chip to do something that causes it to heat up?

After the chip heats up I have to leave it unplugged for 30 mins and then it will begin working again just fine until I try to start discharging from the battery.

I'm attaching screenshots of the software settings and the board for review, hopefully somebody can catch something if its wrong. everything looks great otherwise.