Hello,

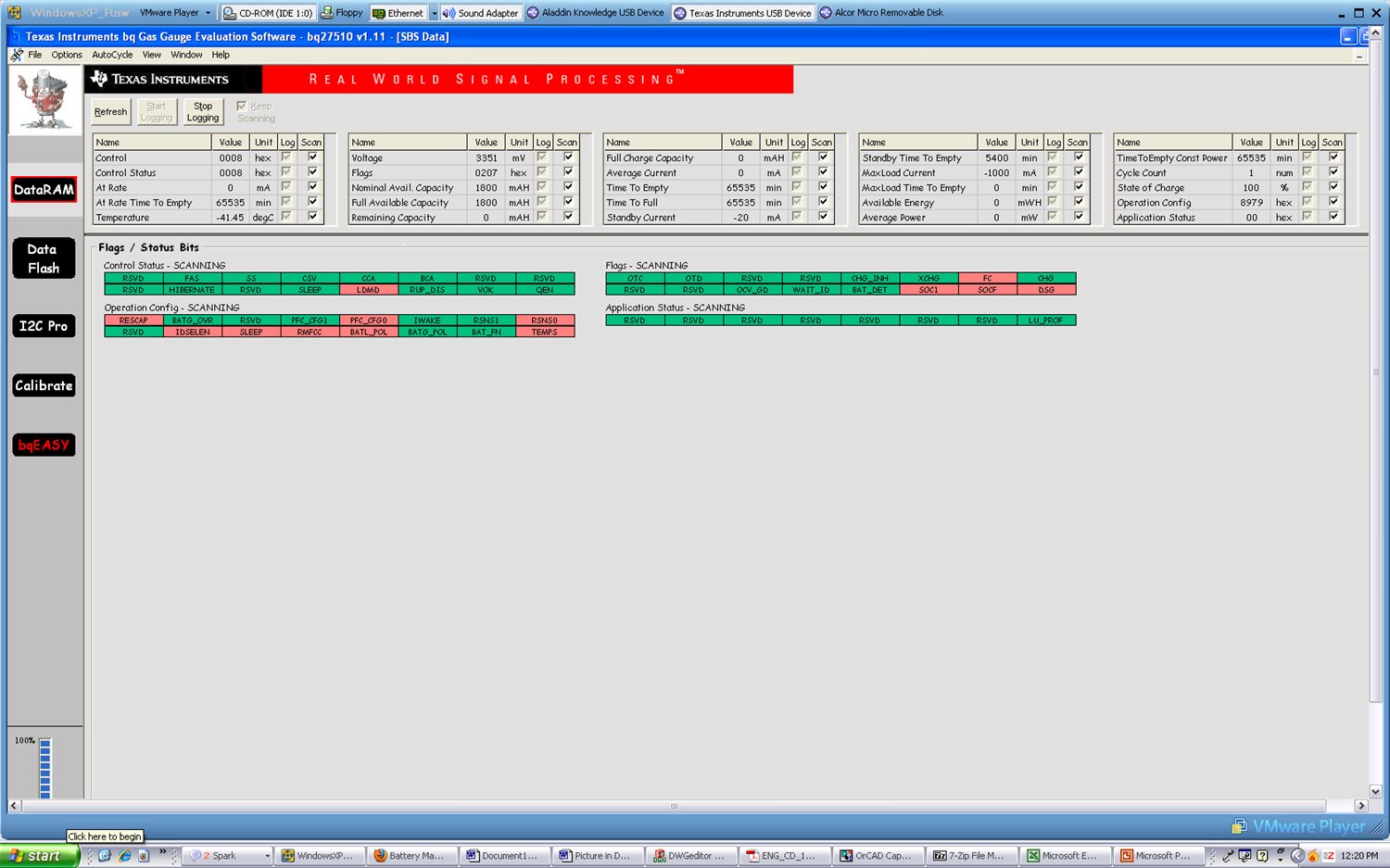

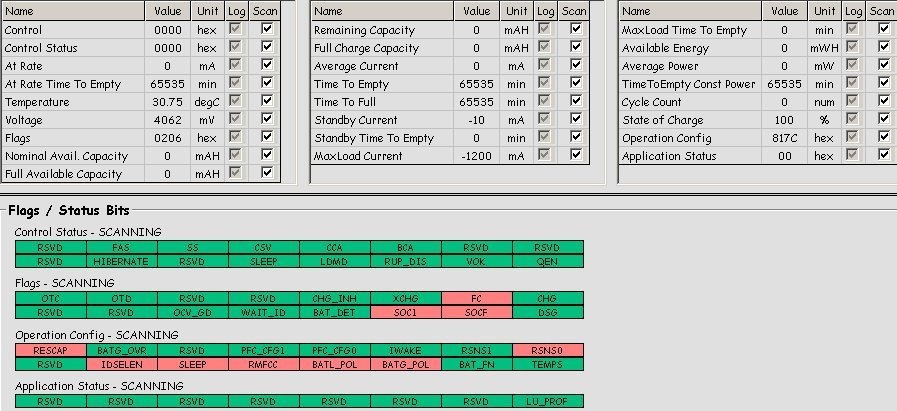

I'm using the bqEasy Software for callibrating my Li-Ion pack. Wen done with the full training I get the following error:

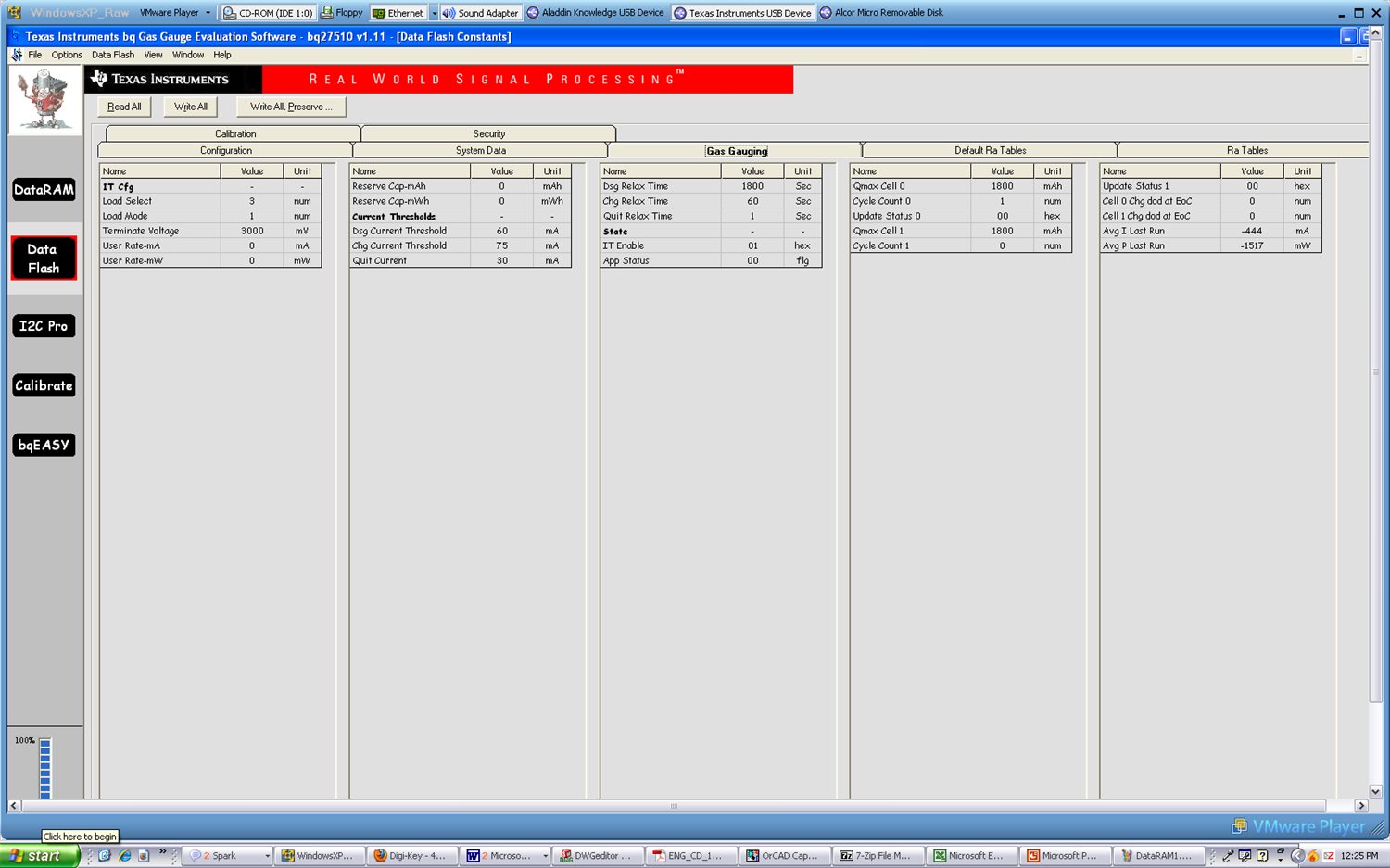

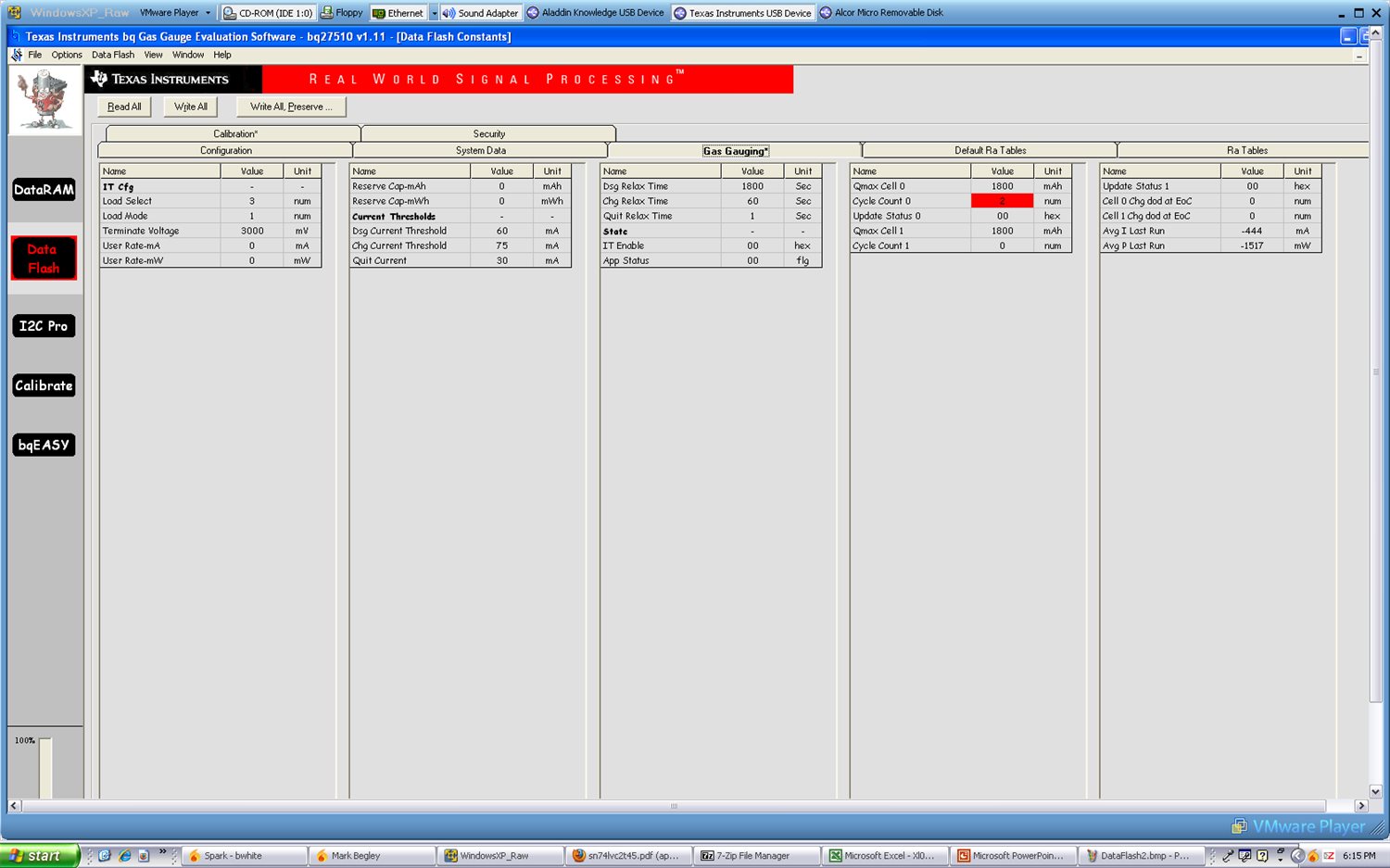

"Dataflash.GasGauging.State.UpdateStatus does NOT = 2. Impedance track learning cycle was not completed correctly. Verify procedure and repeat."

What does this mean. Does the battery have to be fully charged before I click "All Done"

Thanks.