Hi,

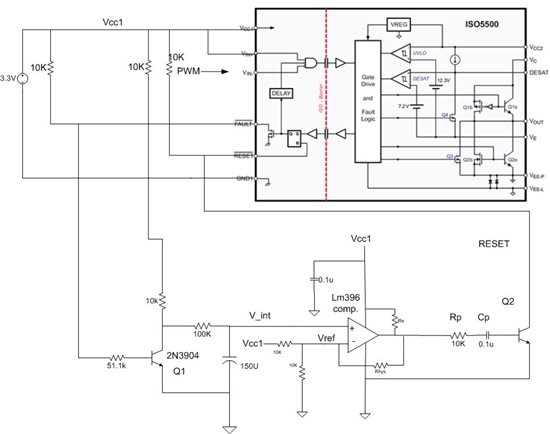

I am student in process of designing a inverter. I will be using the ISO5500 for a full bridge converter, however, I will be using an analog PWM instead of micro controller. If I am using the inverting configuration (PWM will be applied to VIN-), can I connect all the four ISO5500 FAULT to each VIN+ as a safety measure (note no microcontroller is used so the FAULTs are going only to the VIN+ and the bypass capacitor). Also can I control the four RESET manually by connecting the four RESETS to a monostable vibrator (such as 74ls123) and inject a pulse by a push button whenever there is an error ?also can you send me the CAD or the foot print for the device I could not find it . thank you

Majdi