Hello,

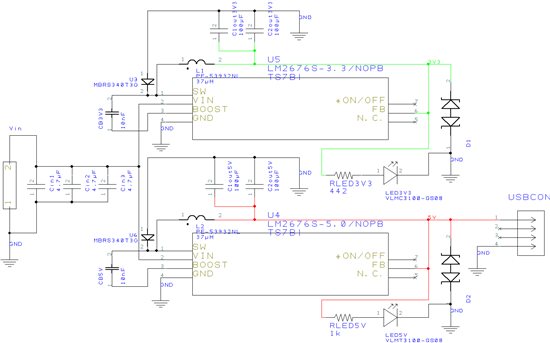

I'm using the LM2676S-5.0 and 3.3 on the same PCB, using the same input voltage. Both are working fine and the 5.0 is powering the Raspberry Pi just fine. I designed the 5V for 2A and the 3V3 for 1.5A with an input voltage of 8-40V using the steps said in the datasheet. This resulted in the following schematic:

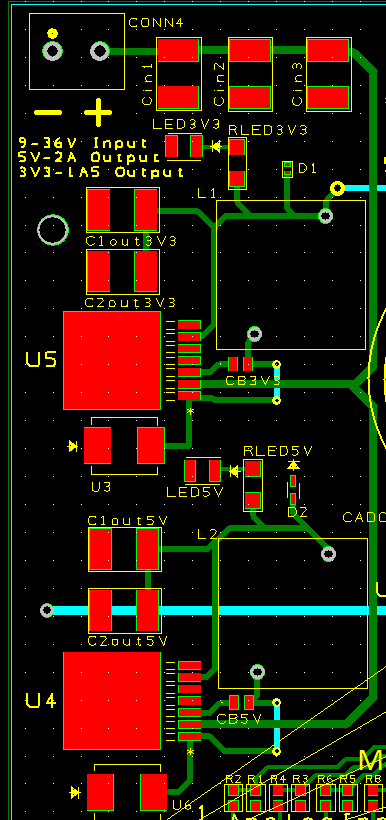

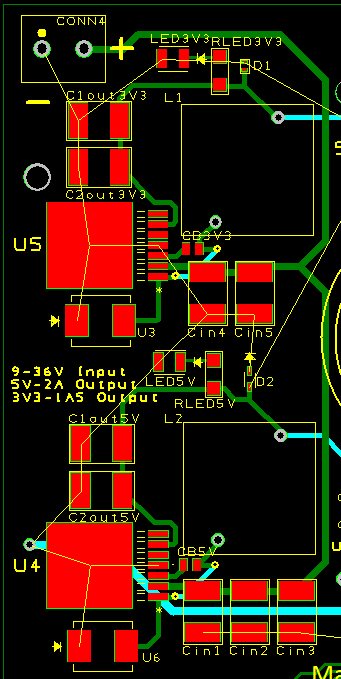

And the PCB design:

Where the top layer is poured GND.

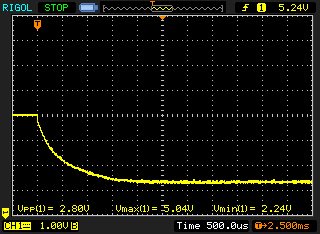

However, today I went to test the load response using an measured 3.3ohm power resistor and the following happened:

The voltage just crashed.. The 3V3 is responding okay but when changing to a 2 ohms resistor it also failed to maintain a proper voltage.

The components used are the following:

Cin = 3x T495D475K050ATE300

Cout = 2x2 TPSD107K010R0100

Diode = 2x1 MBRS340T3G

Inductor = 2x1 PE-53932NL

The only recommendation I didn't really follow was placing the Cin's as close as possible to the LM2676, also it recommended 2x input capacitors for the 3V3 and 3x for the 5V. However, as this is just used to reduce fluctuations on the input I can't see how it would be so destructive for the higher loads. The power supply used for Vin is a 24V/5A Siemens SITOP.

What can I do/change to stop the voltage from crashing down and why is it powering my RPi just fine, while that also draws 700~1A?

Thanks for the advice!