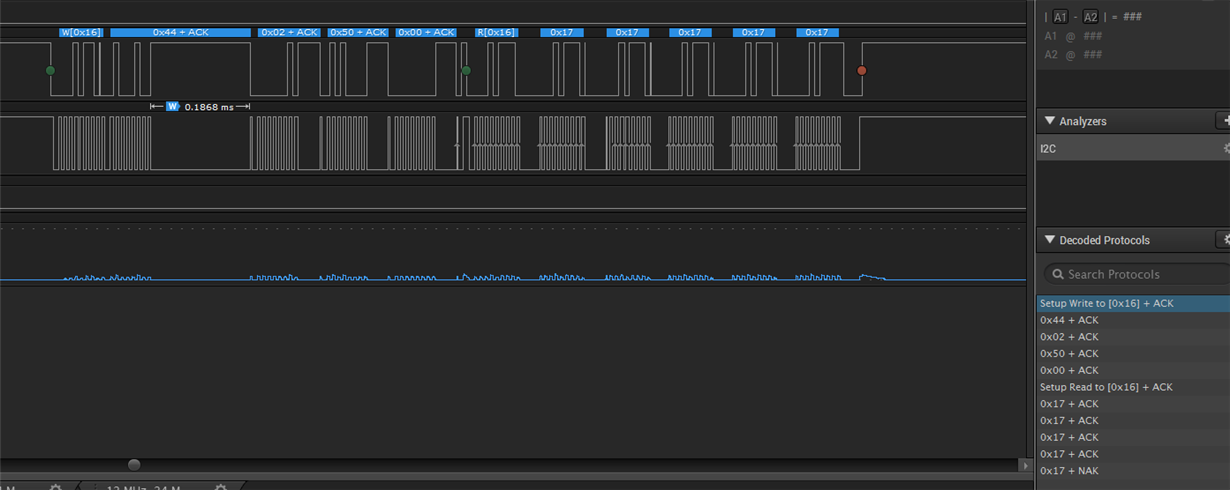

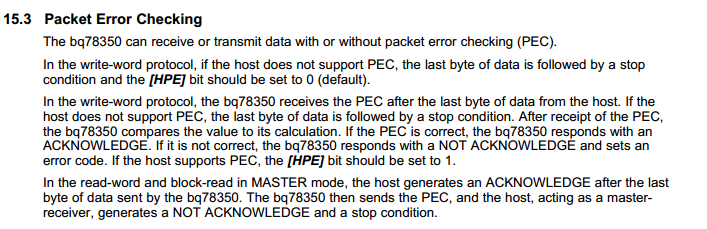

To access the SafetyAlert data, I can use the 0x44 ManufacturerBlockAccess():

0x16 0x44 0x02 0x50 0x00 0x60, then 0x16 0x44 0x17 0x06 0x50 0x00 0x00 0x00 0x00 0x00 0x76

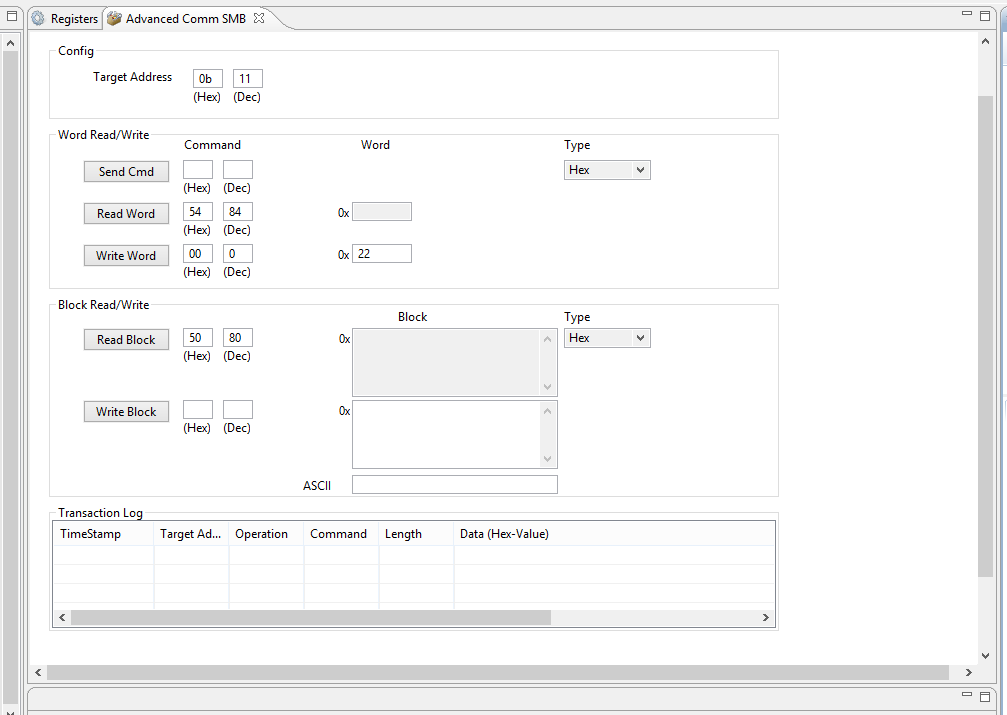

Or Read Block seems to work also:

0x16 0x50 0x17 0x04 0x00 0x00 0x00 0x00 0x05

Is the difference between these two methods that the Read Block for SafetyAlert is not available when Sealed? (And that the Read Block reads RAM, while the ManufacturerBlockAccess() reads Data Flash?)

Thanks.

Tom