Hi,

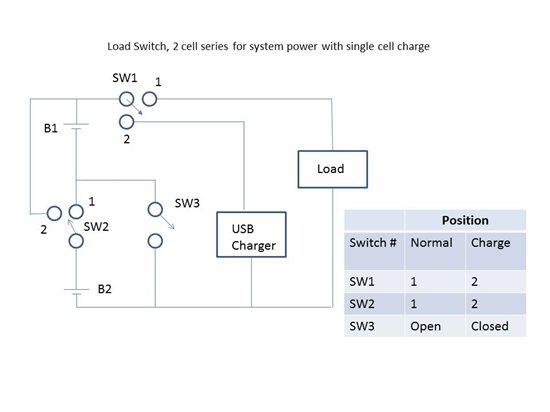

I have a need to charge two LiPo's from a USB port. The application is a simple micro-controller with a motor driven vacuum pump. The total load current is ~125mA for <=30s with a frequency of operation of about 8x per day. The system will automatically detect the presence of a USB connection and there is no need to drive the load during a charge cycle. Charging current can be limited to ~100mA or less if necessary. In the circuit below the idea is to configure the batteries in parallel during the charge cycle and in series when powering the load. I have been investigating TI load switches but they all appear to be limited to a Vin of 8V and two fully charged Lipo's can reach 8.4V. The problem child is SW1 during normal operation.

In any case, it was suggested that I post this in the battery management forum to solicit suggestions to other solutions. Basically I need to charge and balance two Lipo's using a USB connection and be able to isolate the load while charging. Any suggestions for a simple solution?

Thanks, Mark