Hello,

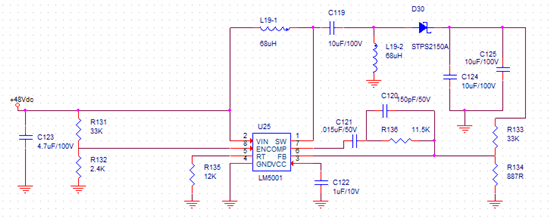

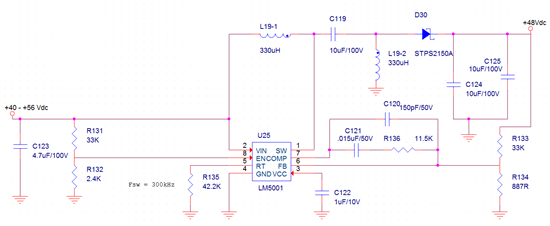

I am trying to design a Sepic circuit that will handle an input of 35V to 55VDC, with an output of 48V, 800 mA. Unfortunately Webench doesn't support sepic designs with the LM5001, so I have had to do my best to calculate the parts I need based on the limited information in the LM5001 data sheet and the 4Q 2008 article in AAJ by Jeff Falin, I came up with the following design:

Unfortunately, after breadboarding the design, it appears to have a limit of about 130 mA instead of the intended 850 mA before it starts flashing on/off. The inductor is a Coiltronics DRQ127-680 dual coil inductor. I'm not exactly an analog or power expert, so I was unsure how to calculate ideal values for the error amplifier/comparator portion of the circuit. I just used the values that were given for the two Sepic examples in the data sheet.

If anyone could look at this design and let me know if they see any obvious issues that would be limiting me to about 130 mA on my 48V output, I would really appreciate it.

Thank you!