Dear All,

I am using the TPS43060 Boost controller with the following design requirements;

Vin: 24V DC

Vout: 52V DC

Iout (max): 1A

The boost controller has been modelled in webench and the TPS43060EVM-199 evaluation board has been modified as per web bench design recommendations switching at 523kHz , see WEBENCH link below;

Below is an image of our modified evaluation board.

We are able to achieve 52V DC @ 1A, although we have a 10V plus voltage undershoot below PGND at the SW Node and on the High Gate drive which could potentially damage the boost controller.

How can we eliminate this undershoot, the datasheet specifies driving the low side gate with 4.7R in which we have done, and by adding additional snubber circutry. We have tried the snubber circuitry although this made no difference.

The BSC340N08NS3 G mosfet selected has a very fast switching characteristics with an rds(ON) of 34mOhms, the 33UH Coil Craft MSS1210-333MEB inductor also has a DCR value of 34mOhm, could this contribute to the undershoot when the low side mosfet initially first turns turns on?

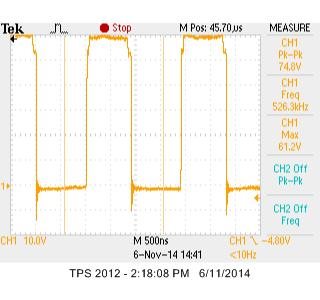

See Low Side, High Side, SW Node and Vout Waveforms below.

High Side Gate Drive with 10V plus undershoot

High Side Gate Drive with 10V plus undershoot

SW Node with 10V plus undershoot

SW Node with 10V plus undershoot

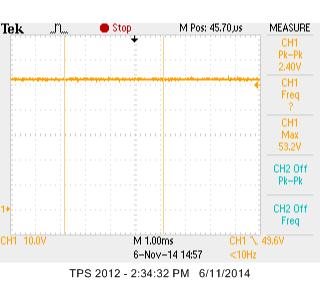

Vout with 470mA resistor LOAD.

Vout with 470mA resistor LOAD.

Would like to add that before changing the mosfet to the BSC340N08NS3G we used the BSC123N08NS3G that came with the evaluation board. This mosfet presented no undershoot and the waveforms were clean. Although we had 80mA of current draw when there was no load, I assume this excess current would be due to the higher gate charge charectestics although as calculated still should not be as high as 80mA. Power efficiency and losses would also prove to be higher so we decided to go for the BSC340N08NS3G which would switch faster and have much better efficiency.

Your help would be kindly appreciated as this is the 3rd attempt to get the booster working before we release the product to the market. Look forward to your feedback.

Kind Regards,

Daniel Haddad

Hardware Design Engineer

Pixel Technologies.