I've designed in bq24232 part. It is a great part but I've notice after charging is complete there is a current drain from the battery while external power is still attached. There are periodic current pulses into the battery.

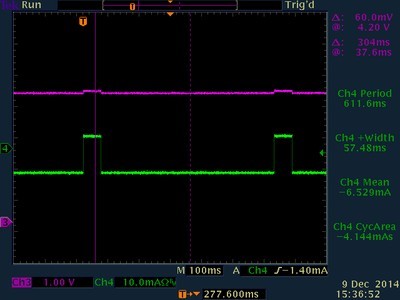

There seems to be a 60mS wide battery maintenance current (17mA) pulse that occurs every 660ms. However, in between these charge pulses the battery is discharging by 8-9mA . Using a digital o-scope and integrating from one charge pulse to another shows an average discharge rate of 4.1mA.

From battery datasheet we are using it starts the battery is a polymer Li-Ion, 110mAHr with a nominal 3.7v voltage and 4.2v charge voltage. Given the capacity and average discharge of 4.1mA we'll need to recharge the battery in 10-11 days.

Once charged, the battery will slowly discharge until the some threshold where bq4232 part will initiate a charge cycle. Is this the way the bq24232 should operate?

This seems to wear out the battery unnecessarily.

Thanks for your support.