Hello,

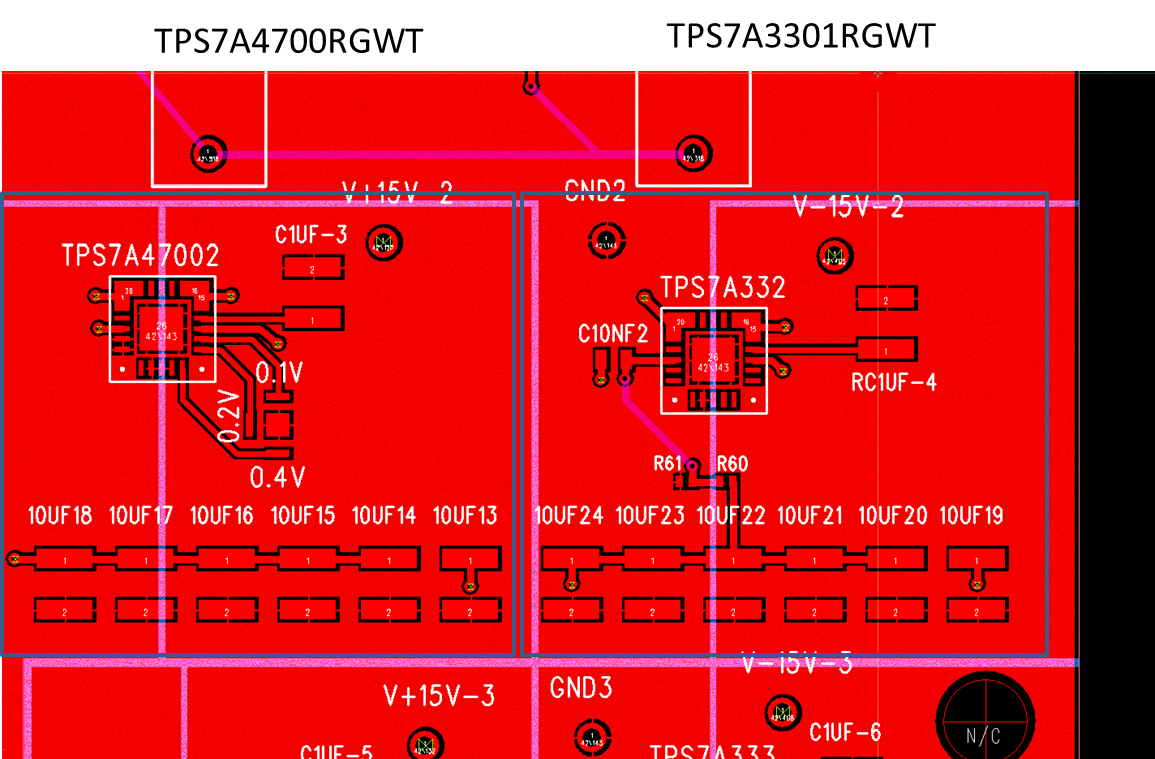

I have designed the two devices output to be +15.8V and -15.2 V respectively. While when Vin<~15V, Vout~=Vin, when Vin is approaching 15V, the devices start to burn. I have checked the connection, I believe they are correct as suggested. While there might be some issues in the thermal pad connection and I have used vias to connect the capacitors, I believe there might be other reasons for my failure. Could anyone have any idea? Thanks!

Best,

Min