Hi,

I support the TI PMIC solutions (TPS659xx) for OMAP3 family. TPS65950 has an integrated battery charger module which can be used for charging single cell Li-Ion battery.

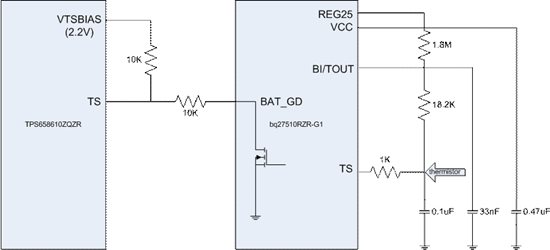

I have a customer who will use the integrated charger and the BQ27500 fuel gauge. I need some help to determine how TPS65950 and BQ27500 can be connected on the system. Please help me with the questions below:

1. Is it necessary that BQ part should be connected to the battery thermistor? Can we connect a 10K to BQ instead of actual thermistor?

Reason to ask the above question: TPS65950 ADCIN1 pin must be connected to the thermistor, it acts as a battery detection for the device. If BQ part doesnt need to be connected to thermistor and still can function normal then that will be ideal. I dont know if temperature sensing is essential for gauging purpose.

2. BQ specs mention that the thermistor can be shared, but in this case TPS65950 may not read the accurate resistance (based on the thermistor current) to report the correct battery temperature.

I am trying to understand the best connectivity for these parts.

If further discussion is required then I can meet someone in Forest Lane or can have a phone call in case the support person is outside Dallas.

Customer will be finalizing schematics and I need to ensure we help them soon.

Thank you.

Gandhar.