Hello everybody,

I need your help on the following.

Our application has not a stable load, we are driving a brushless motor for 1s and stop it for one more second, and do it again all the time. We made the learning cycle as requested on stable load, everything was ok except at the end where some warnings appeared during the writing of certain value (?) but the golden file was finally created.

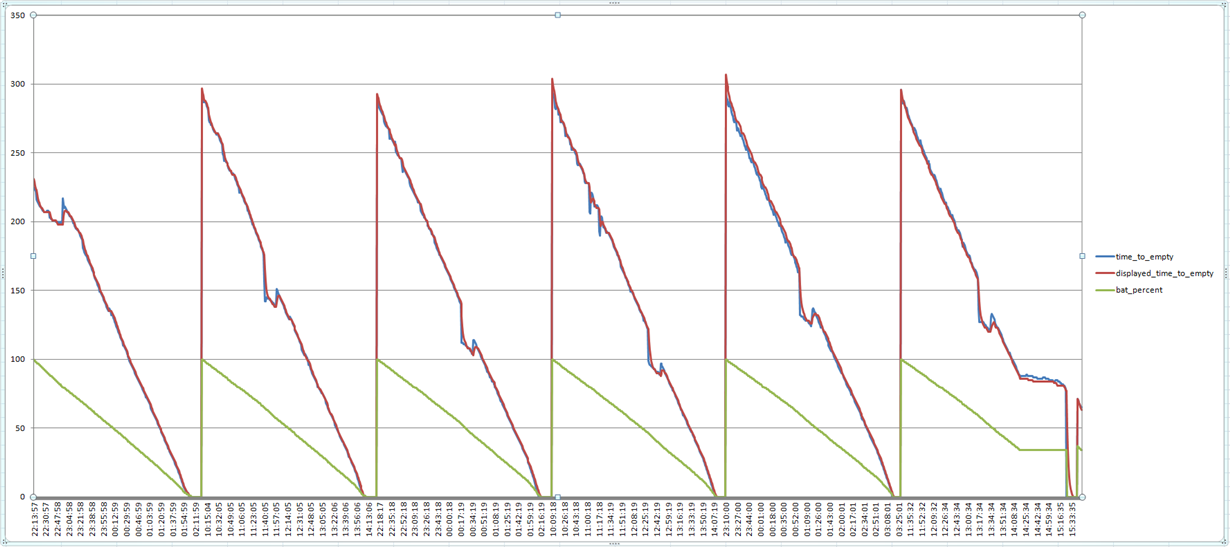

When we are making test, most of time everything is perfect - see the 4 first cycles on the file attached. But, sometimes - see the last cycle on the attached file, at the end of the cycle, the value given by the gauge stays stable during ~1h. On the example attached, the StateOfCharge does not move to 31% for ~1h, and the TimeToEmpty is changing a little bit during the same time. And suddenly, the values recover the correct values !!!...After one hour !

Is somebody understand what could happen ?

Where are reading the gauge every 1s, is it too much ?

Could we thing that the learning has wrote bad values somewhere ?

I really appreciate your help on that because the product is ready to launch and we need this function running perfectly.

Many thanks for your contribution