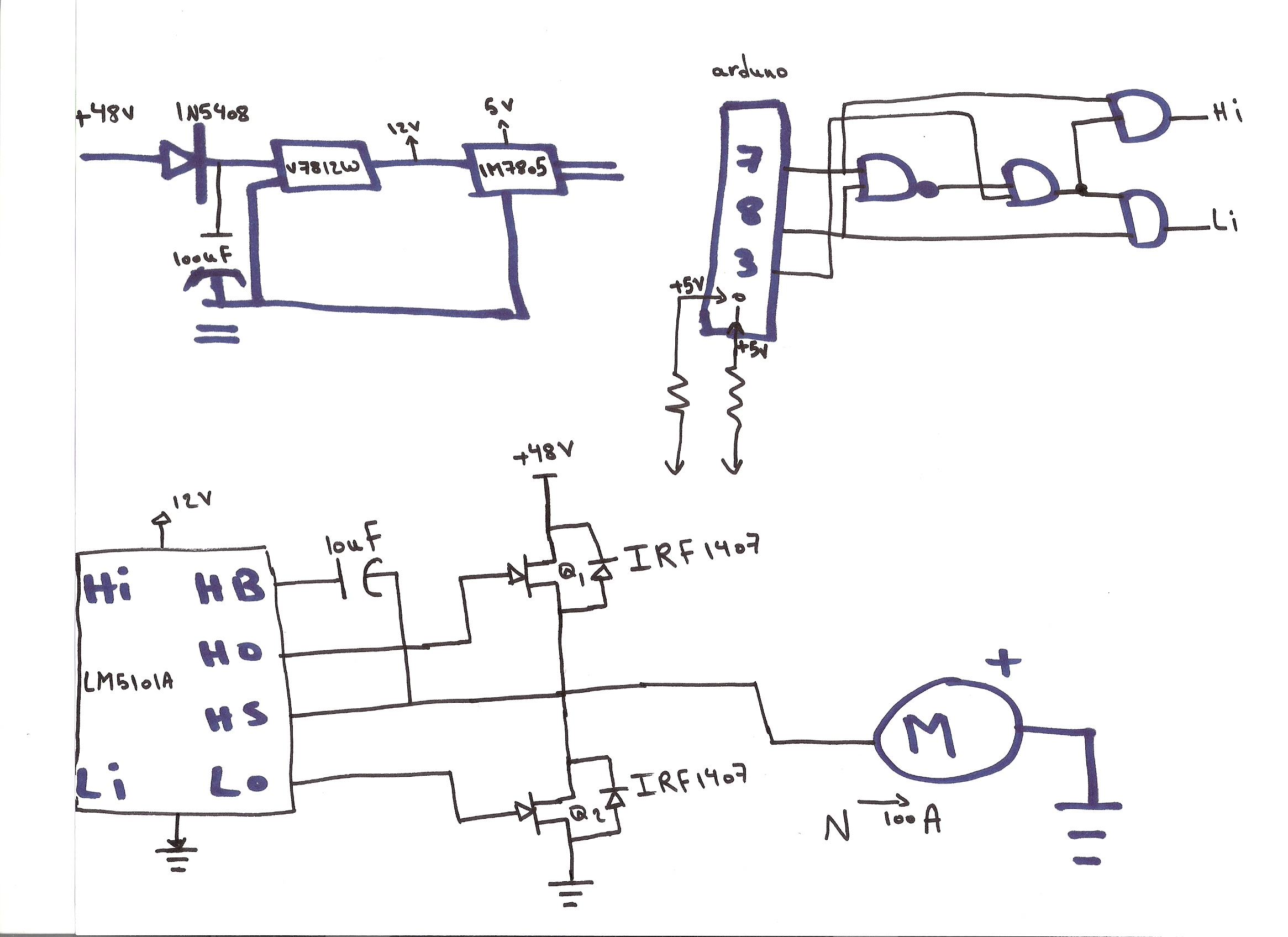

Hi.. I am new and am trying to put togather a cheap simple motor controller for a series wond DC motor. I currently deisgned a small circuit with an Arduino Uno to provide PWM and high/low side inputs pulses. I have logic to prevent both high and low inputs from becoming 1 at the same time (using AND and NAND gates). I am using 2 car batteries in series for power. They are connect to an Ada fuit module to generate the 12V connected to the Vdd of the LM5101A. HS and HB are connected to 10us electrolyte cap (for C boot strap). The HO and LO are connected to the gate of the high and low side mosfets (IRF 1407 TO220), respectively. The motor spins and we can control the speed using the Arduino Uno (connected to a Pot). However we occasionally burn the LM5101A, but only after we power the entire circuit off then leave it for a whilw then we try to start it again and move the Pot then we see the LM5101A over heat.

We suspect that noise might be causing the low side to turn abruptly (highest possibility).

We also suspect that current is flowing from Motor to LM5101A through the HS (not sure if that is possible).

If anyone has seen this issue please let me know.

I also have many questions about this chip:

0. How do I calculate the C boot strap if I want to drive 10 of IRF1407.

1. How can I know if the LM5101A is getting shorted? Meaning can I measure the current at Vdd to see if it is trying to draw more current than it can handle (how can I tell how much current does it draw)?

2. Is it possible for any current from motor or any where else to flow to HS (connected to drain of low side mofet, source of high side mosfet and motor)?

3. Does any current flow out of HS to the motor?

4. How much heat can an LM5101A take before it gets damaged?

4. Are there any protective components or circuits that I need to add to protect the LM5101A (caps, resistors, etc)?

Appreciate the help in advance.

Thanks

Basem.