Hello all,

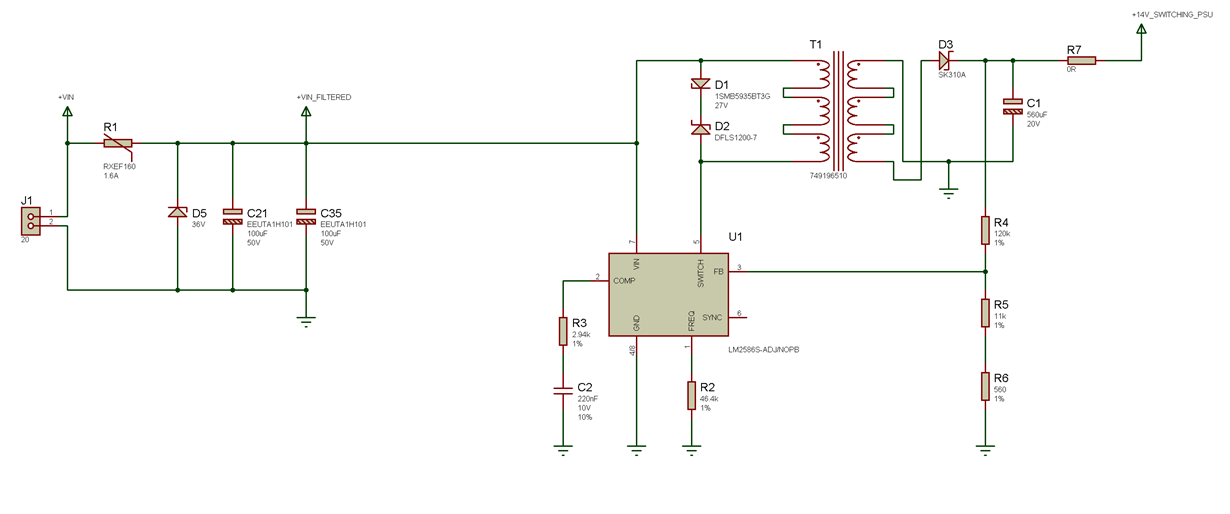

I'm using the Workbench to design a 14V flyback switching regulator. The design can be found at http://webench.ti.com/appinfo/webench/scripts/SDP.cgi?ID=258A678DA273F45E

The transformer recommended by Workbench, the Wurth 749196510 ( ) has 3 primary and 3 secondary windings.

) has 3 primary and 3 secondary windings.

Am I correct in saying that the transformer should be wired with the 3 primary windings in series and the 3 secondary windings in series? i.e. like the following: