Hi,

I have an optimized firmware with my Lead acid battery.

In fact, I learned to BQ optimized cycle, Chem ID... And everything is good.

Now, I want to verify gauge in my application. So I charged my battery and everything are OK.

But after that, when I discharged my battery under ~ C/2 I have a big problem:

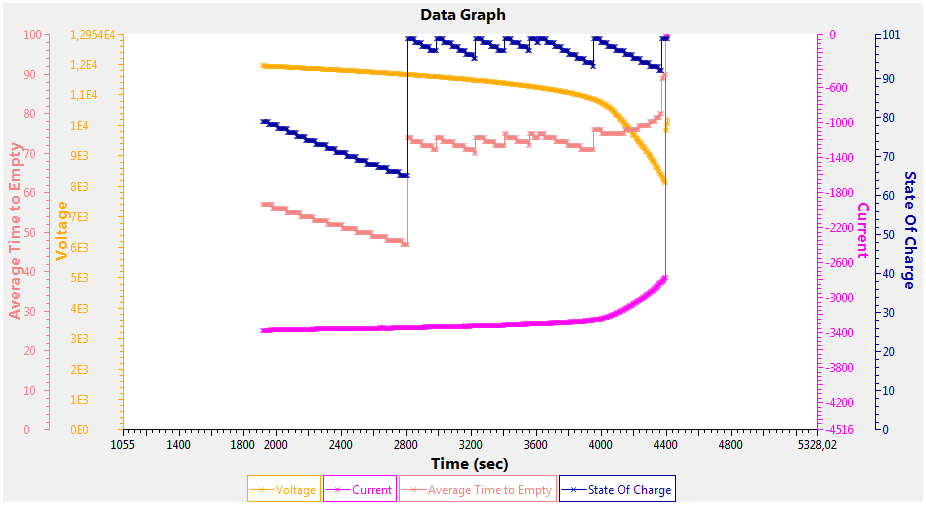

Average time to Empty and SOC is too high at the end of discharge. See this below:

The discharge of battery are stopped under 8V ( < Vcell terminate voltage)

you can see that SOC = 20% and average time to Empty = 22min, it's a big problem for knowing cut of battery !

Can you explain why ?

Thank you,

Best regards,

Loïc