Dear ,

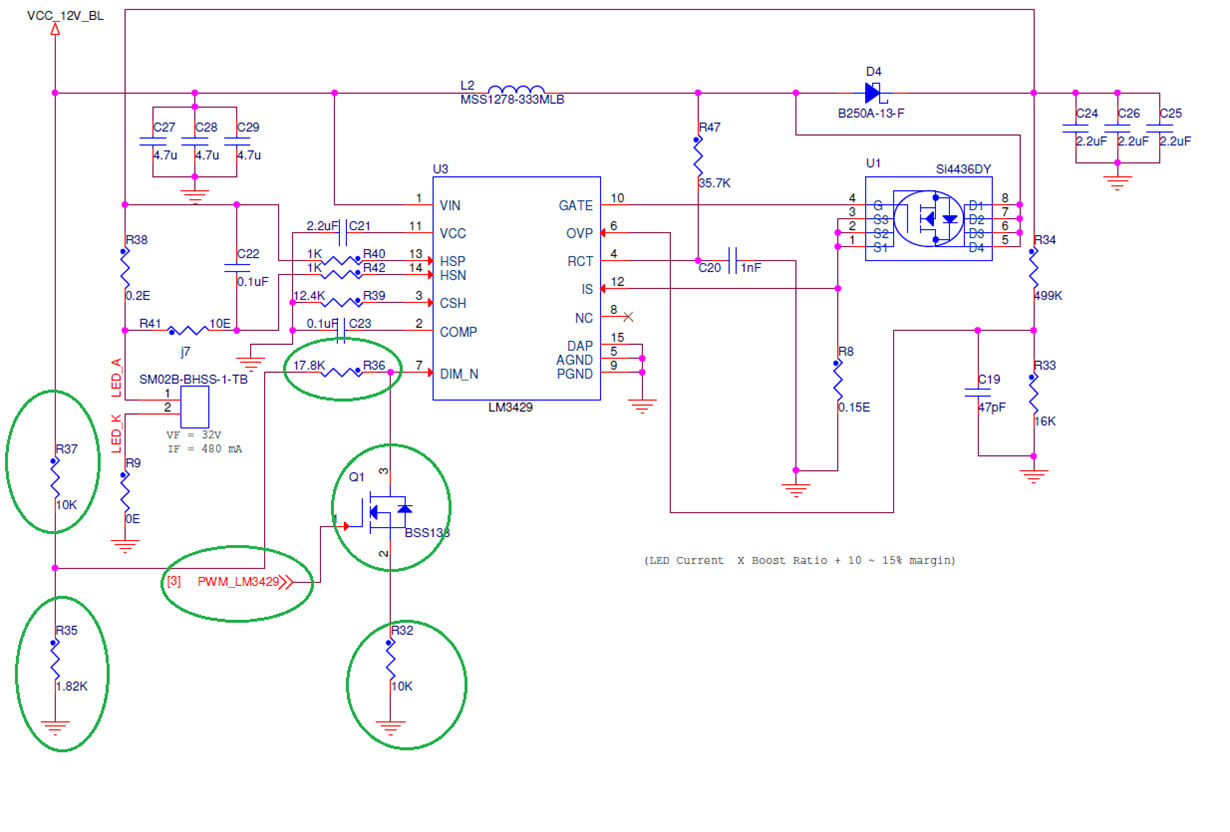

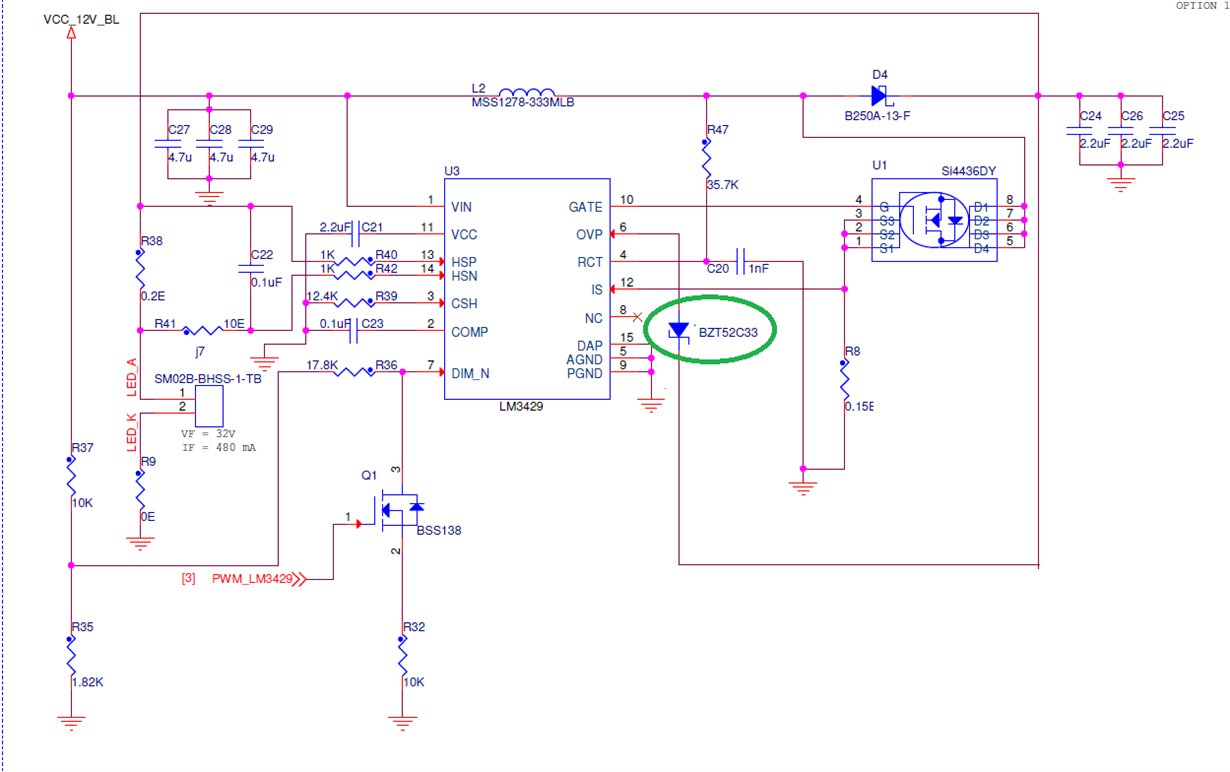

Here I'm facing one problem. The LCD is not displaying data by default. When I probe pin DIM_N (pin number 7) using multimeter then only LCD is displaying data properly. Could you please review my schematic and let me know that whether my PWM connection is proper or not ?

Regards,

Azlum