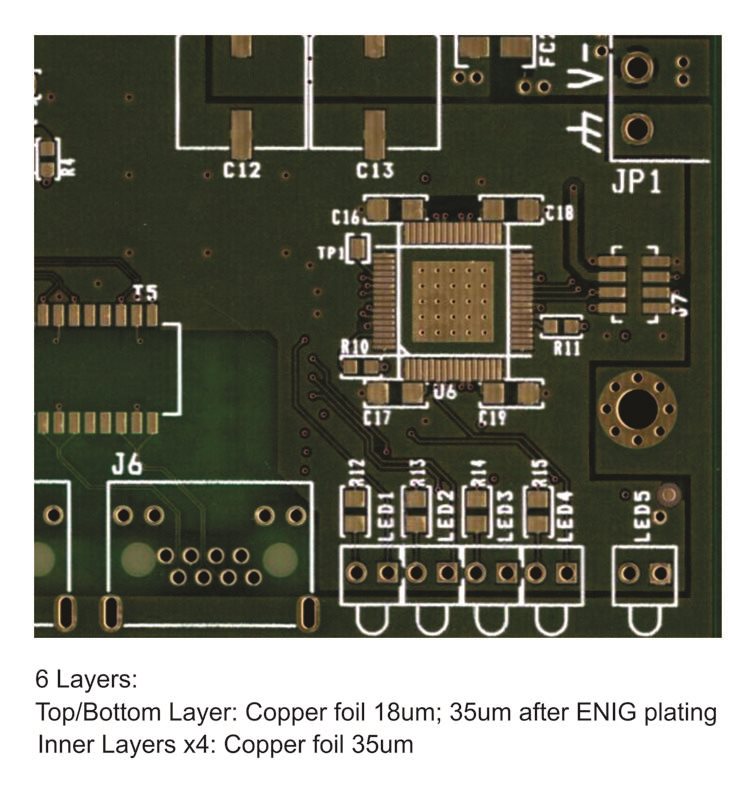

I'm using the TPS2384PAP in a design. With a 48V supply and the 4 channels loaded with about 13.5W each, the case (top center) temperature is about 58 deg. C, which is about 20 deg C higher than the TPS2384 on the HPA109 eval board under the same conditions. The voltage drop between the "Nx" pins and "RET" pins are the same between the 2 boards. I can't see any reason why my design would dissipate more power, so I am left to believe it's the pcb heatsinking. What is the copper thickness of the HPA109 REV. B board? My board is 6 layers. thermal vias under the PowerPad connect the top layer to 2 internal ground layers and the bottom layer. See picture. Should my top layer be at 2 oz. copper? Any ideas why the TPS2384 on my board is running hotter?

-

Ask a related question

What is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.