I am having an issue that is causing the BQ24600 to fail catastrophically when hot plugging a battery into the charge circuit when no adapter voltage is present. I am using a high capacity Li-Poly battery that can source a large amount of current.

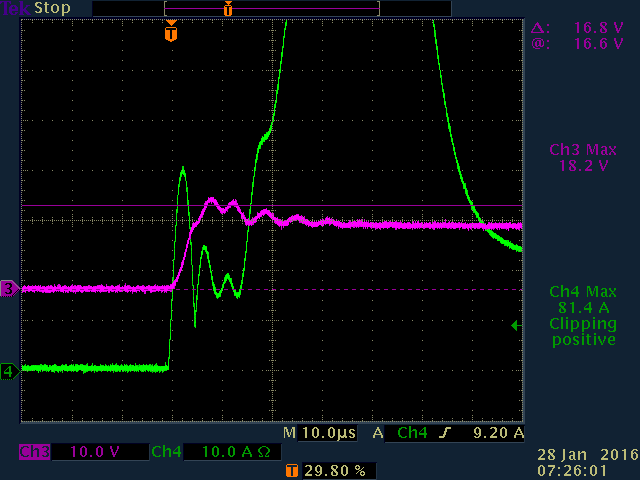

I initially thought that the failure was caused by a voltage transient caused by charging the ceramic output capacitors causing the battery voltage to rise beyond the absolute maximums of the part. However, I have seen failures when the battery voltage is well within the tolerance of the part. Below is a scope capture of my board failing when hot plugging in a battery to the output with no adapter voltage present. You can see the battery voltage slightly ring when the battery is plugged, however, VBAT only reaches 18.2V prior to the failure. Shortly after, the circuit failed and you can see an extremely large current spike as the IC failed which resulted in the current sense resistor to finally fail open, fusing the circuit.

I have removed the 0.1uF SRP and SRN capacitors to ensure there was no current flowing to these nodes as noted in another post on a similar issue. I ahve also reduced the output capacitance to Qty 2 10uF ceramic capacitors as well as trying to add a 47uF aluminium output cap paired with a 17.1V tranzorb, none of which has resolved the problem though it has severely limited the voltage transient.

CH3 - VBAT, CH4 - Battery Current

Below is a screenshot using the same battery on the evaluation module. The voltage transient is much higher than what I am seeing on my board, but the IC and sense resistor do not fail. Therefore, I am not convinced the voltage transient is the root cause of the problem and perhaps some other portion of the circuit is causing the failure.

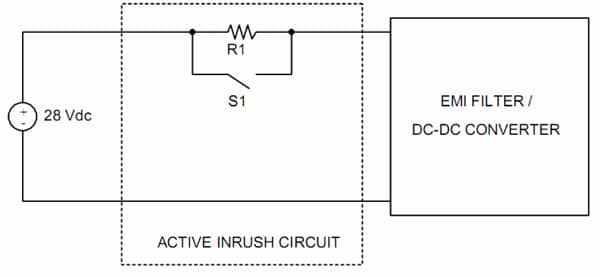

My reference circuit is below. I am using slightly different FETs and I do not have a 4.7 ohm resistor from the D1 to the BTST node that is included in the evaluation module, but not the datasheet reference circuit. But these are the only major differences I can see between the circuits. I have adjusted the output capacitance to 20uF total ceramic capacitance matching the evaluation module with the same failure as shown in the scope capture above.

Any ideas on what actions could be taken or scope traces I could capture to help isolate the issue would be appreciated. The failure is catastrophic and I have damaged multiple boards which is making the issue very hard to debug.

Thanks,

Alex