Hi,

We have a 15V power source (LIPO battery) that we need to regulate down to 5V to power a BeagleBone Black (BBB) board. Currently, we are testing the circuit with simple power resistors as our load (so as not to damage the BBB). We designed the circuit according to the datasheet and get a clean 5.2V unloaded output. As soon as we connect any kind of load (tested at 42mA (120ohm) and 1A (5ohm) loads) the output gets loaded down to anywhere from 0-3V. In any case, it is clearly not capable of sourcing the required current. Relevant components listed below:

Schottky Diode: MBR360 (ON Semiconductor) 60V, 3A

Inductor: 10uH (Abracon LLC AIUR-06-100K) 5A

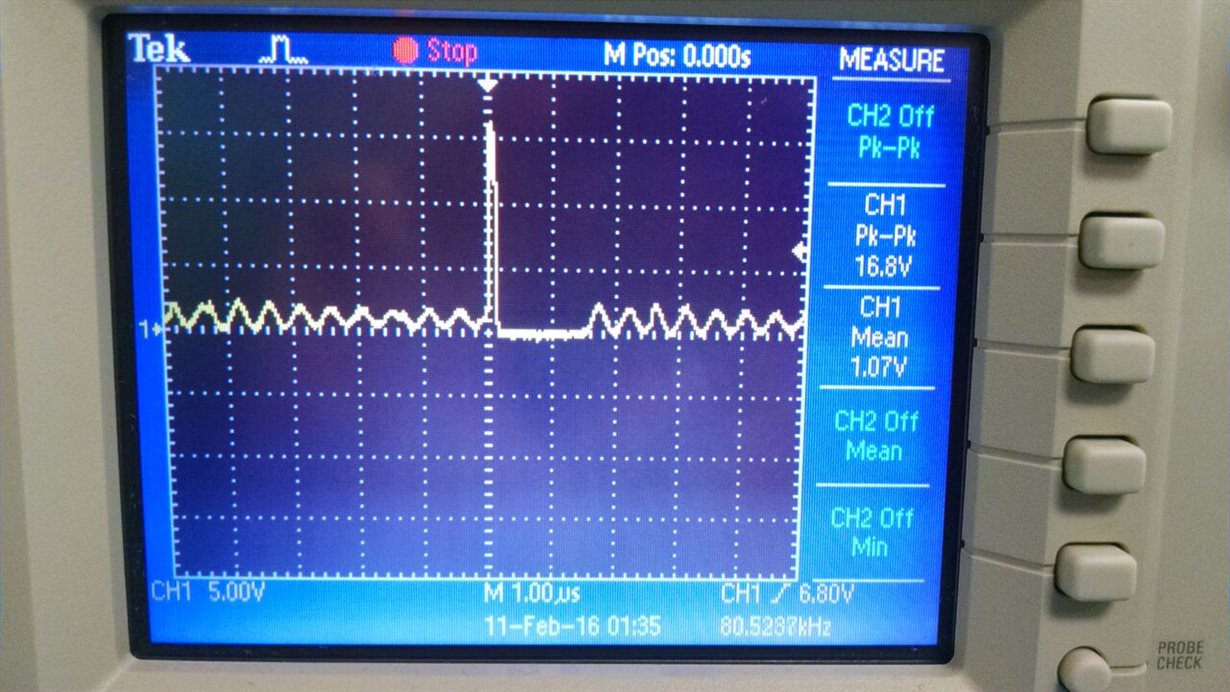

I should also mention that we are using electrolytic capacitors for the input and output bulk capacitance (against the datasheet's recommendation). With smaller ceramic capacitors we get noticeable ripple on the output voltage. In a past design using this same chip, the electrolytic capacitors did not create a problem.

We tried two different chips (both of which work in a separate circuit that regulates 15V to 12V) and have replaced the Schottky diode and inductor with (equivalent) known good parts. We have tried many values for the output filter cap including both ceramic and electrolytic. We designed expecting our BBB to typically pull 1A. The BBB website recommends powering the board so that up to 2A can be provided. Thus, we designed figuring a max 2A current draw. The chip is capable of up to 3A so we figured this would be ok.

The one thing that kind of worked was replacing our 10uH inductor with a 39uH one that was in the lab. This worked for lighter loads (got a clean 5V out for the 42mA load) but still did not work for the 1A load. The inductor used was Bourns Inc. RLB9012-390KL

Perhaps we need a different inductor? I'm not sure if this is indeed the case, but if so please advise as to how to select a proper inductor for the application.