Hi,

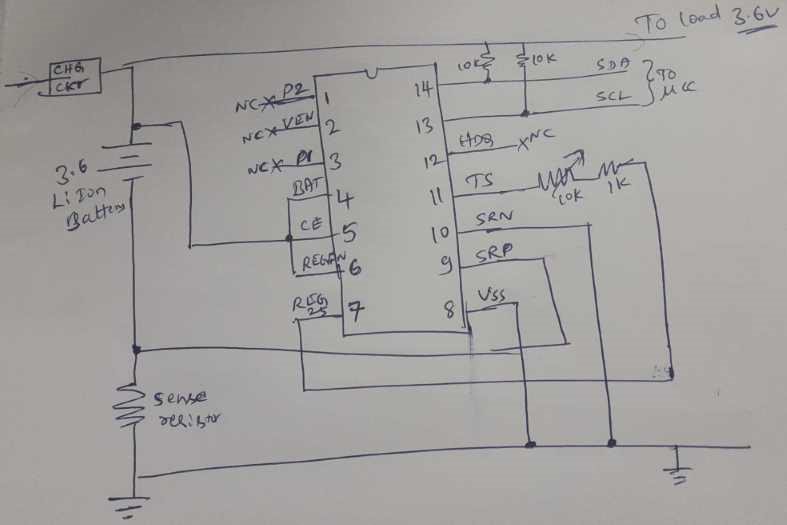

I am planning to use BQ34Z100-G1 for fuel guaging. I got the sample and when I tried to read throgh the data sheet/ application note - I was not able to figure out how do I connect this guage to Battery and communicate with some micro (planning to use variant of ARM7) - as my requirement is not using any FET, No LED's and as less components as possible - as I am using only one LiIon battery (around 3.6V). Below is the circuit I thought (after going through) data sheet and google. Can some expert here - give me review this? My ckt is shown below (NC - Not connected)

Also also any simple "guide" for s/w intialization and reading the bare minimum things like total charge, remaining charge, % of battery etc.