Hello,

I am using the TPS65150 following the typical application circuit in the datasheet. I only have problem with VGH

VS = 10.4V OK

VGH = 16 V , desired , design values for R5=1M, R6=82K --> this resulted in a much higher peaks that is not good for LCD.

currently using R5=1M, R6= 87.5K, C4=C16=0.33uF.

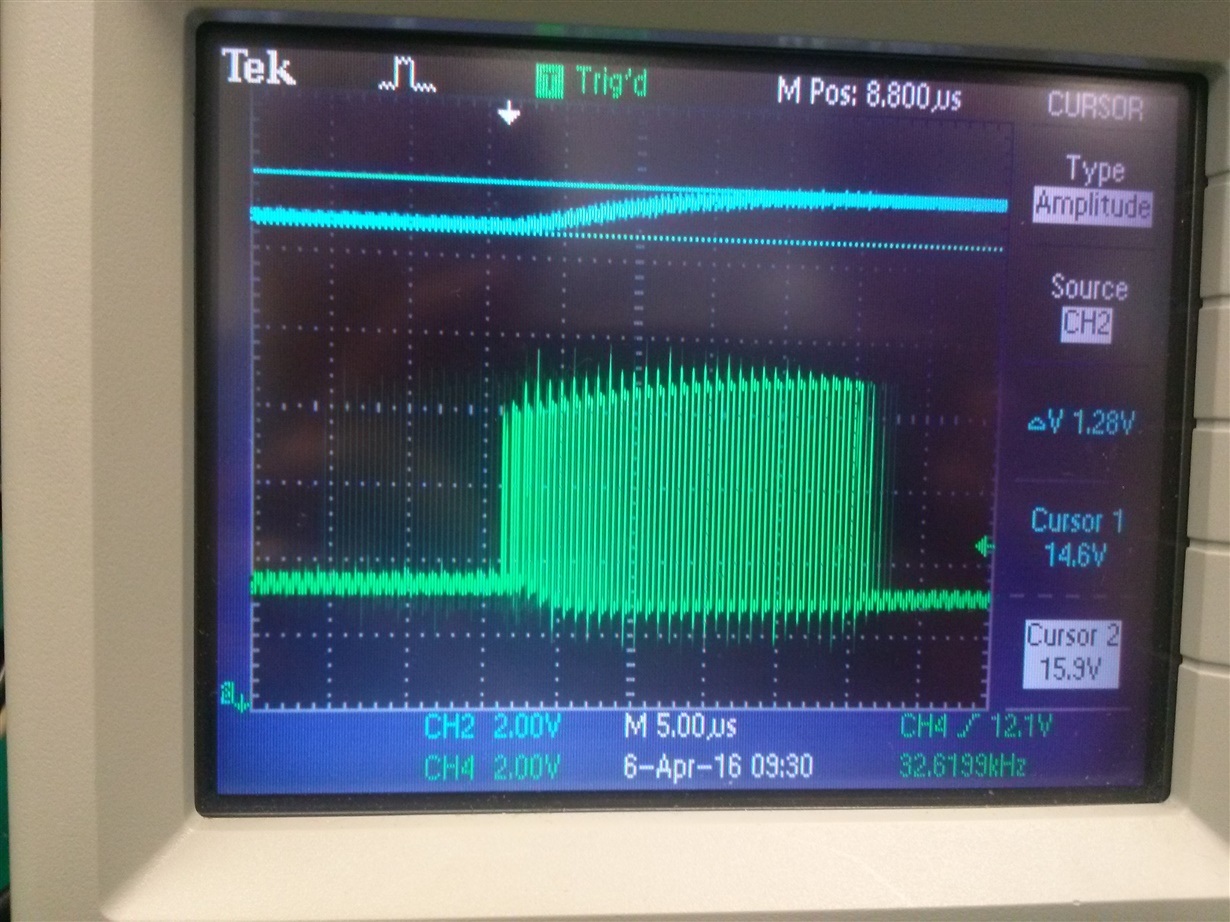

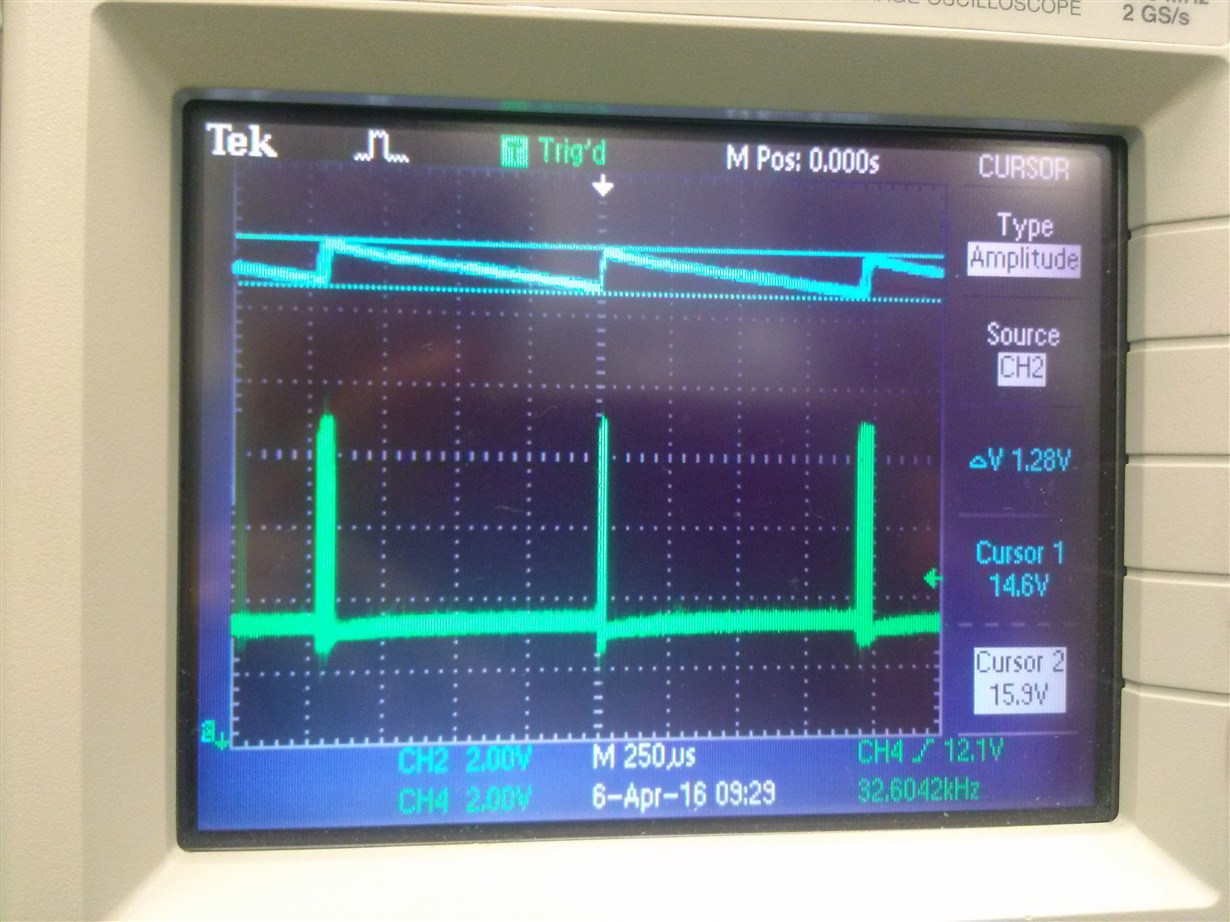

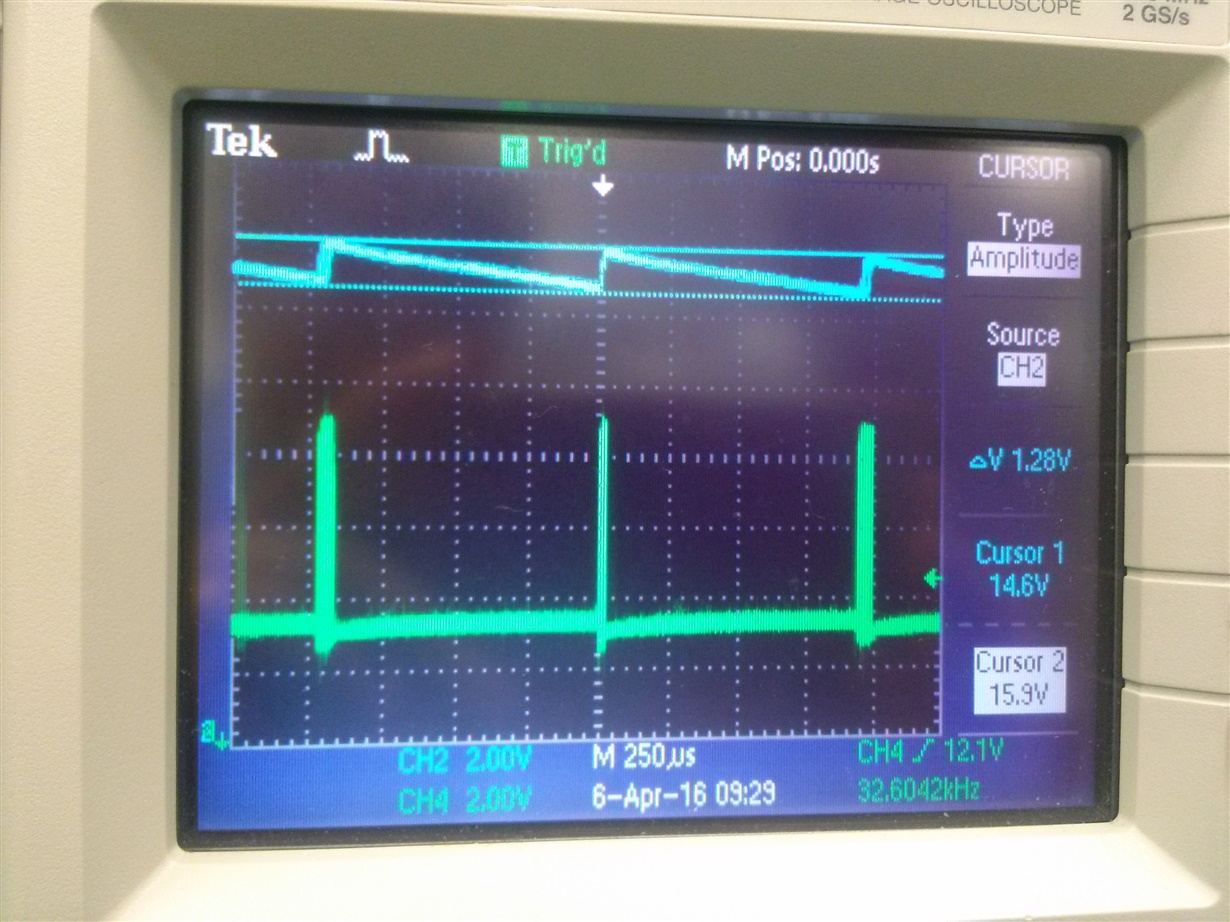

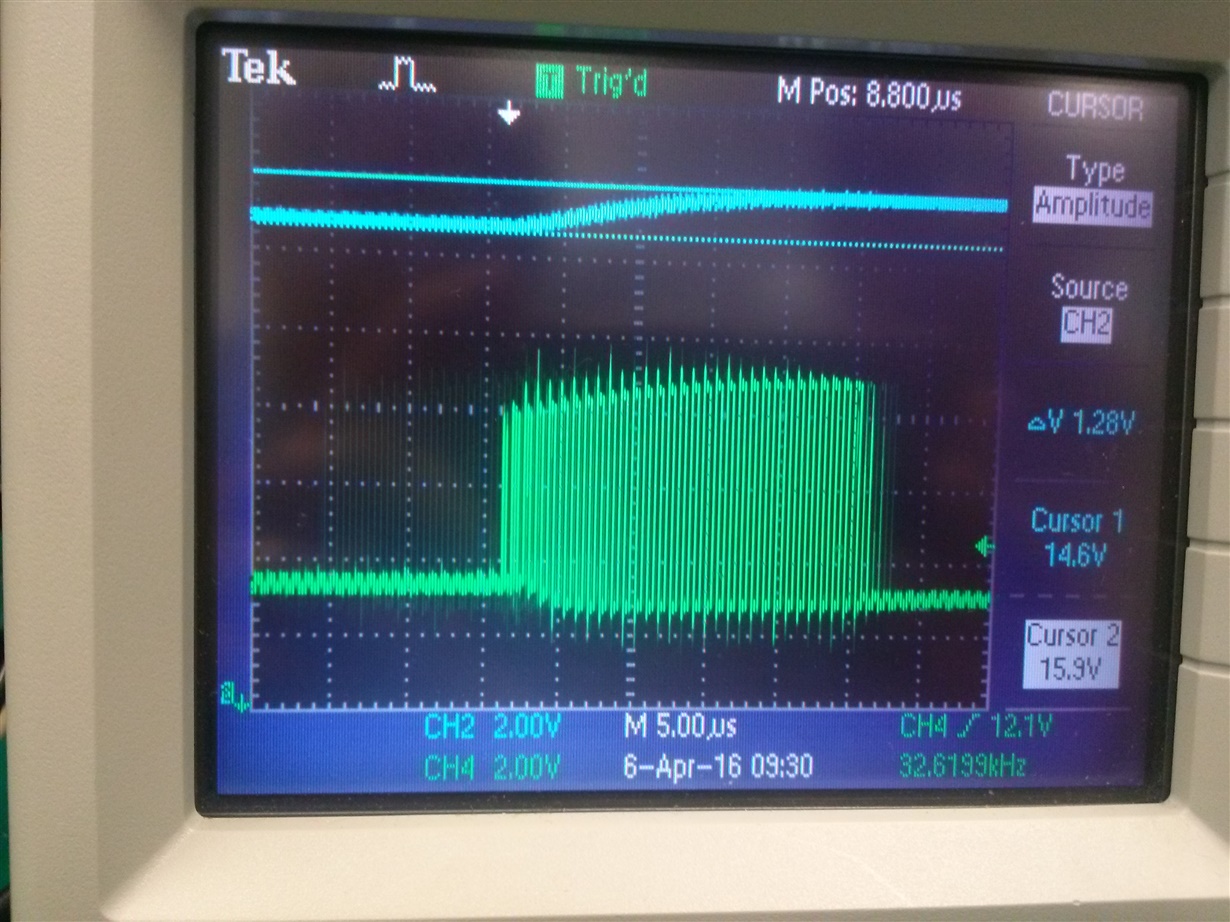

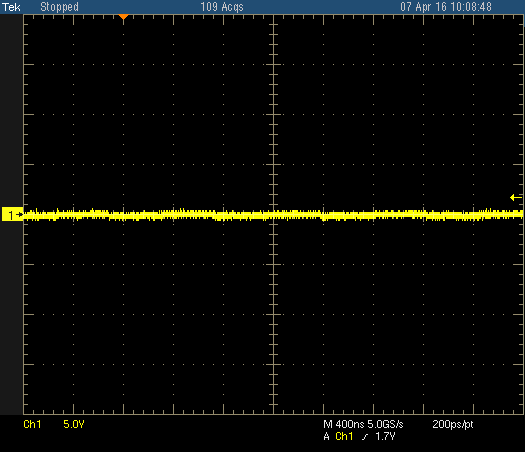

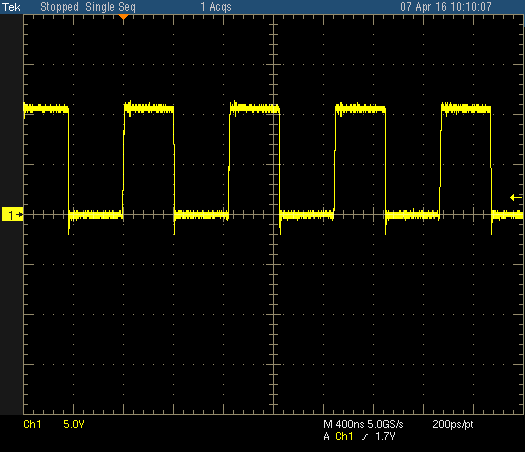

The CPI output is a sawtooth peak = 17V , trough = 15.8V, LCD is not stable.

I measuring the ANODE of D5 I can see burst of 1.2Mhz pulse when that creates the 17V peaks of the sawtooth output, following by no pulses and the output drops to about 15.8V and the burst comes in to raise the output back to 17V.

Is there a need to change C4 and/or C16? There is no spec regarding the how much current that LCD needs.

Please help.