I am testing out the TPS61088 on my own board. I have followed the suggested layout very closely and the components used are very similar to the evaluation module.

Cin 44uF ceramic (2x22uF + 100nF)

Cout 67uF ceramic (3x22uF + 1uF)

Inductor 1uH 5A 10mOhm

Feedback resistors 590k and 68k ohm

comp 20k and 1nF

Rfsw = 226k

Rilim = 226k

Css = 100nF

All the small components are 0402.

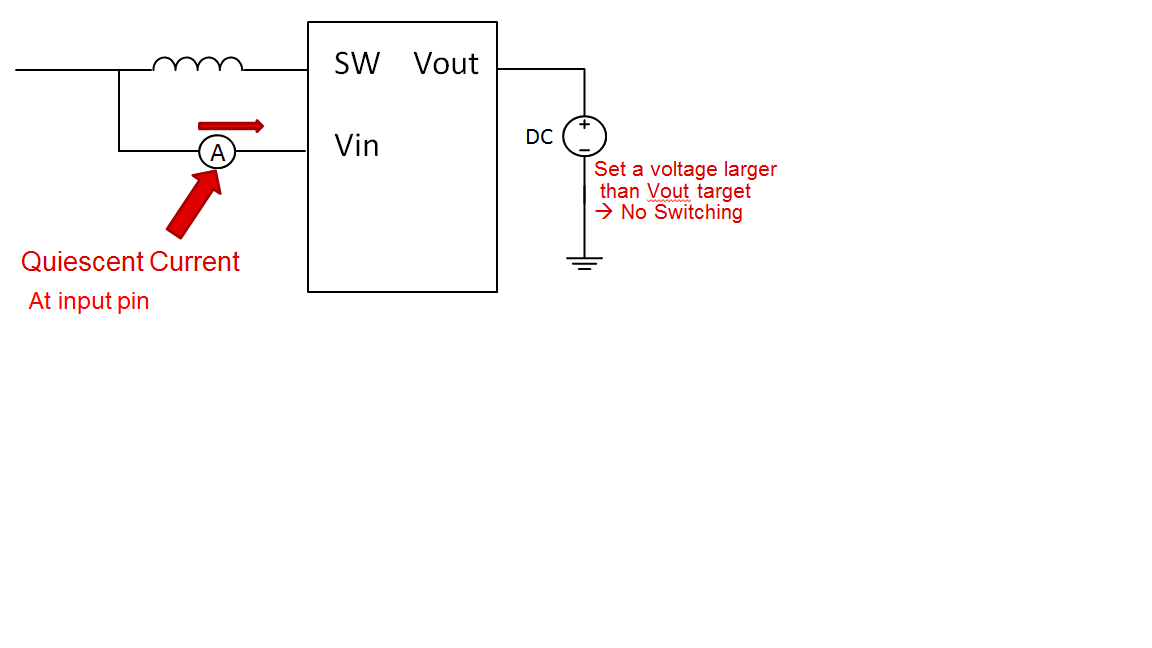

I am struggling to get the quiescent currrent down to 100-200uA uA as suggested in the datasheet. It seems every time I build and solder the board I get a different quiescent current mA draw. 5mA, 8mA, 12mA, 9mA. It keeps changing every time I re-solder the board or check, clean and replace the feedback or comp components.

I had a similar problem with the evaluation module board. I replaced the feedback resistors to change the output voltage to 12V. I had to clean and re-solder these resistors 5 times before I could achieve 470uA quiescent current as I kept getting several mA current draw. This is still higher than 100uA suggested

So it seems that the component is very sensitive to how the IC and the feedback components are soldered and it is very hard to achieve the low quiescent current reliably.

Can you offer any advice as to how to make this more reliable? I'm sure in production using reflow soldering things might be more reliable, but I should be able to get it to work in prototype.

Thanks in advance

David