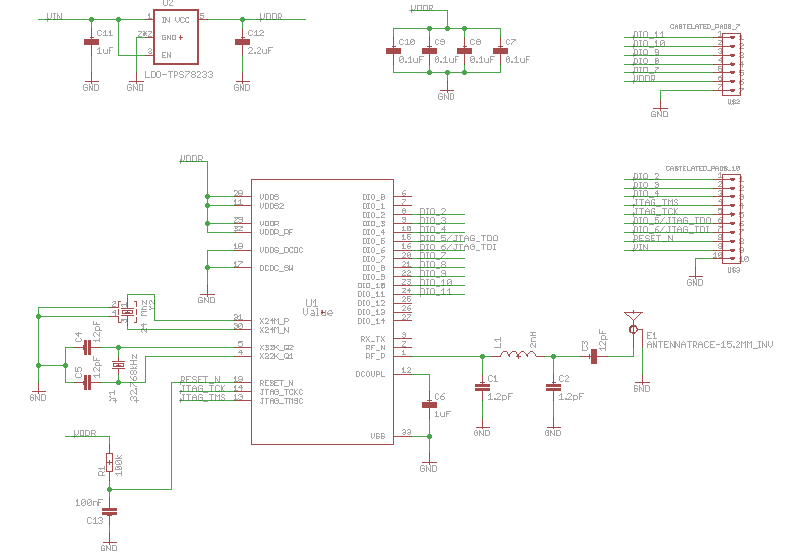

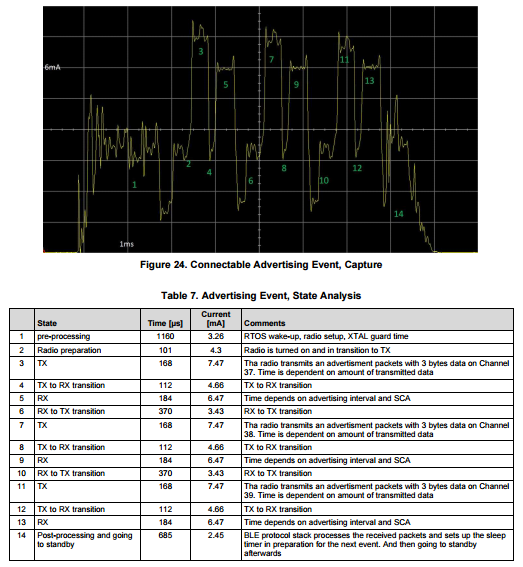

I made a module with the cc2640 powered with a external regulator (TPS782). As i explain in a previous post i was suffering strage behavoir when i tried to comunicate with the bluetooth. It results that the power output of the TPS782 was droping in the transitions from the low current load of the cc2640 in sleep mode, and the relative high current in communication mode made that the voltage drops below the minimun voltage of the cc2640 and it resets.

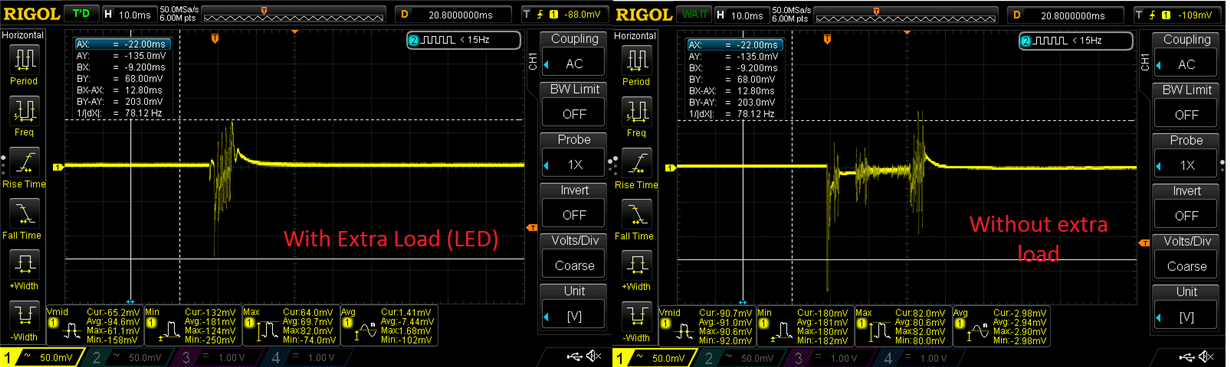

If i put some extra load on the output of the regulator it works ok. There are some grpahs of the output voltage of the regulator:

In the graph of the right the extra brusts after the first one are caused by the reset of the device.

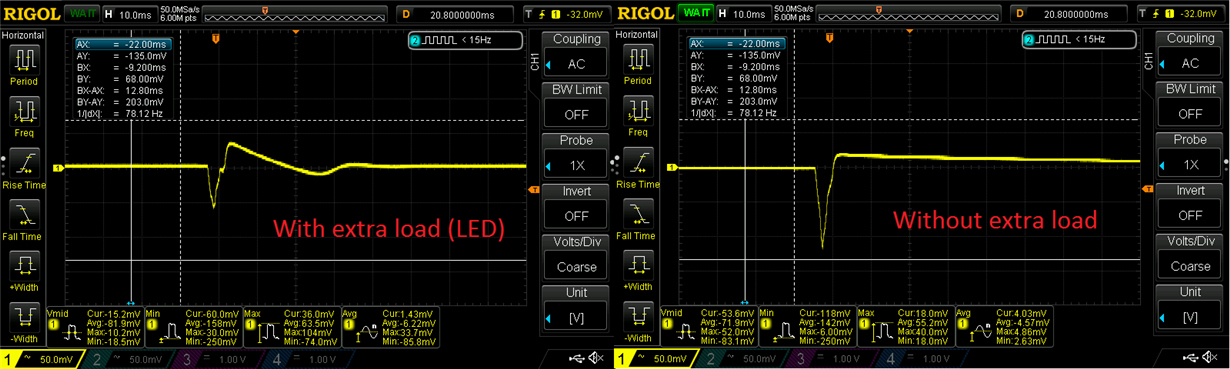

I tried puting some extra capacity on the output but it didn't work until i used a 100uF electrolitic capacitor. The graphs with the extra capacitors:

This is not a solution, i need a better filter, and i have no experience in this field, could you sugest me a better solution?

Thanks.